THERMAL HARMONY!

Achieving Thermal Comfort in Intimate Apparel

Continuing our exploration into the overall comfort experience of intimate apparel, our focus now shifts to the critical aspect of thermal comfort. Understanding the complexities of heat regulation and achieving thermal comfort are vital aspects to delivering a superior customer experience. This blog post explores the intricacies of thermal comfort in intimate apparel, offering valuable insights and innovative solutions tailored for entrepreneurs and start-ups in the industry.

UNDERSTANDING THERMAL COMFORT

Hygroscopicity of Underwear Fabric

The transfer of moisture from clothing to the environment involves complex routes like diffusion, wicking, sorption, and evaporation. The ability of fabrics to absorb sweat takes precedence over water vapour permeability in determining overall comfort. Factors such as fabric thickness, tightness of construction, and the hygroscopicity of fibers play key roles in moisture management. For instance, highly hygroscopic wool fabrics are perceived as drier than polyester, which, due to its hydrophobic nature, can lead to static issues like cling during wear.

Factors Influencing Thermal Comfort

Six key factors, including air temperature, air movement, humidity, mean radiant temperature, body heat production, and clothing, are involved in thermal comfort. Understanding how these factors interact is important to ensure optimal thermal regulation for creating intimate apparel that adapts to different climates and individual preferences.

Heat Transmission

Intimate apparel acts as an essential interface for perspiration and heat transmission from the skin to the environment. The thickness and porosity of fabric, particularly in women’s shapewear, can impact thermal comfort. Entrepreneurs can explore various knit structures to optimize thermoregulatory responses. Balancing breathability and support is crucial to avoiding discomfort and potential health issues.

INNOVATIONS IN THERMAL COMFORT

To combat issues related to moisture absorption and promote thermal comfort, innovative fibers have emerged. Examples such as Meryl Nexten®, Thermolite®, Aerocool®, Becool™, Coolmax®, Akwatel, and phase change materials (PCMs) are revolutionising the industry:

1. Meryl Nexten®: European-Made Polyamide Fiber

Meryl Nexten® boasts being 25% lighter than conventional garments of the same thickness and provides 25% greater insulation than other hollow fibers. This European-made polyamide fiber redefines lightweight comfort and insulation in intimate apparel.

2. Thermolite®: Hollow Core Hydrophobic Polyester Fiber

Thermolite® is a hollow core fiber known for its rapid drying properties – 20% quicker than other insulating fabrics and 50% faster than cotton. Its hydrophobic nature enables quick heating, effective retention of body heat and prevention of radiation heat loss.

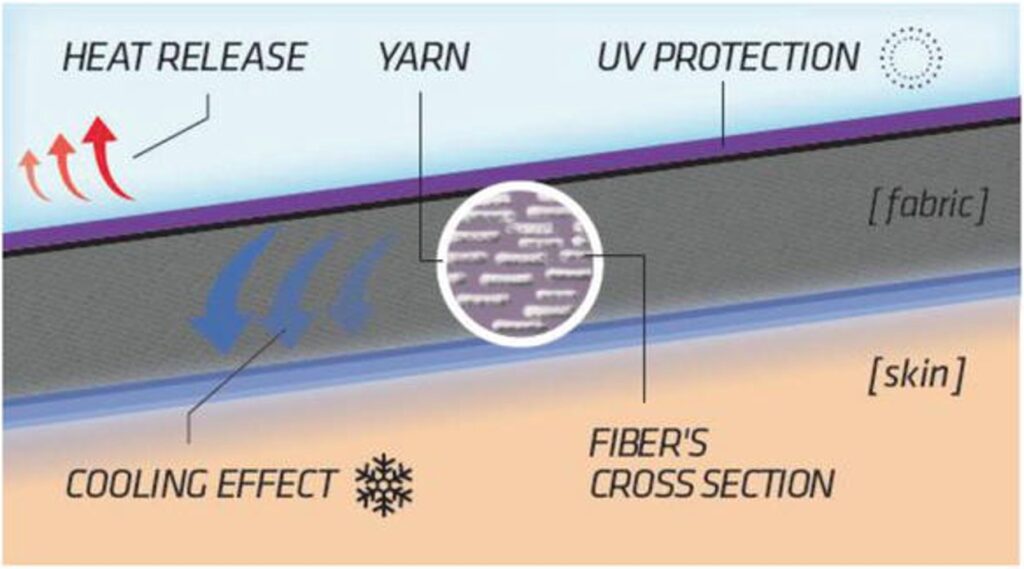

3. Aerocool®: Cross-Shaped Polyester Filament Yarn

Aerocool® features a cross-shaped polyester filament yarn designed for rapid absorption, evaporation, and fast drying. Its unique ‘four-leaf clover’ cross-section facilitates moisture movement through four capillary tubes, ensuring a comfortable and dry experience.

4. Becool™: Nylon and Polyester Blend

Crafted from a blend of nylon and polyester, Becool™ enables rapid skin drying and temperature maintenance. Its innovative four-canals fiber cross-section ensures efficient water drainage, surpassing the diffusion capabilities of traditional materials.

5. Coolmax®: Moisture-Transporting Fabric

Coolmax® fabric excels in moisture and heat transport. The four-channel fibers swiftly move moisture and heat to the outer surface, ensuring rapid drying and breathability—ideal for designing sports bras with superior moisture management.

6. Akwatel®: Polyester Fabric with Electrochemical Principles

Akwatel® polyester fabric utilises electrochemical principles for moisture transport and thermoregulation. Modified at the molecular level, it releases hydrophilic groups, actively transporting water molecules to the atmosphere before they can form into liquid water.

7. Nike® Sphere Cool: Mesh-Structured Fabric

Nike® Sphere Cool features a mesh structure that accelerates sweat evaporation, providing a cooler and more comfortable experience. Its inner layer’s exceptional moisture absorbency adds to the overall comfort of the wearer.

8. Phase Change Materials (PCMs): Thermal Storage

PCMs offer thermal storage capabilities controlled by heat absorption and release during a phase change. Selecting a PCM with phase changes aligned with skin temperatures is crucial for intimate apparel, ensuring adaptive temperature regulation.

Understanding the unique properties of each moisture management fiber allows entrepreneurs to tailor their offerings to specific customer needs. Whether it’s rapid drying, effective heat retention, or enhanced moisture absorption, these fibers provide a toolkit for crafting intimate wear that goes beyond mere functionality, offering a blend of comfort, style, and technological sophistication. Foremost, prioritizing thermal comfort is not just a design consideration but a strategic imperative.

Our exploration is ongoing. Stay connected as we uncover the mysteries of achieving sensorial, motion, aesthetic and hygienic comfort in the sphere of intimate apparel!