WIRE WITH CONFIDENCE

Bra Wire Grading for Intimate Apparel Entrepreneurs and Start-Ups

Greetings, fellow intimate apparel entrepreneurs and start-ups! Are you ready to revolutionise your wire selection game? We know the struggle of finding the perfect bra wires for those wired styles – like searching for a needle in a haystack! But fear not, because we’re about to unveil the secret sauce of bra wire grading. Get ready to embark on a journey that will transform your customers’ experience. Let’s dive in and revolutionise the way we wire!

UNDERSTANDING THE CHALLENGES

- Limited Coverage: Traditional bra wire designs cater to only a small portion of the female population. But neglects the wide range of breast shapes and sizes.

- Incompatibility with Breast Shape: The inflexibility of materials, mainly steel, used in bra wires often fails to conform to the natural shape of the breast, leading to discomfort.

- Lack of Detailed Measurements: Due to a scarcity of comprehensive body size surveys specifically focused on breast dimensions, the wire shape dimensions remain poorly understood.

- Concentrated Pressure Points: Ill-fitting bra wires tend to exert excessive pressure at certain points on the body. That causes discomfort and potential health issues.

THE IMPACT OF WIRE SIZE VARIATION

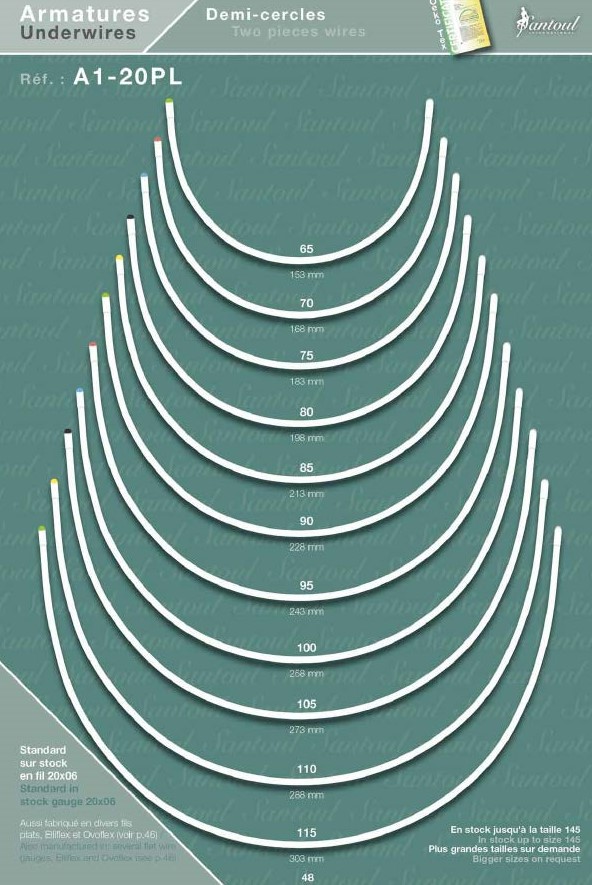

- Inconsistent Industry Standards: Each commercial bra wire supplier has its own standard wire size for a specific bra size. That often results in inconsistency across brands and confusion for consumers.

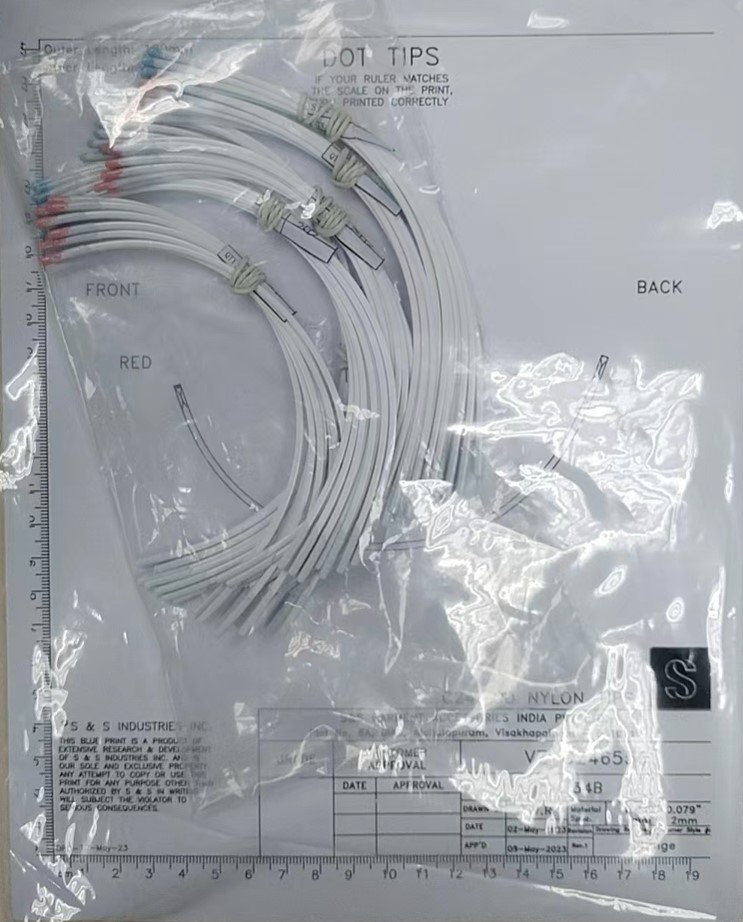

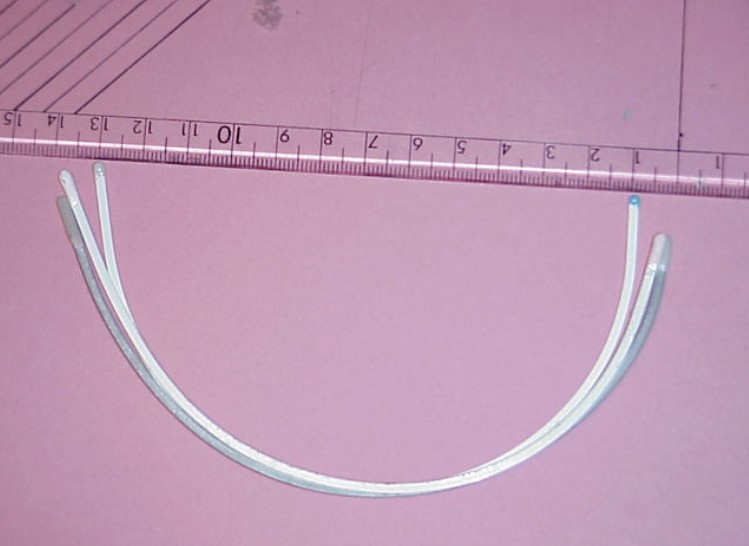

- Understanding Size Variations: The below photograph demonstrates three variations of 34B wires. Here the opening widths between points vary by 20 mm. Considering a 6 mm increment per size, this translates to a difference of three bra or cup sizes.

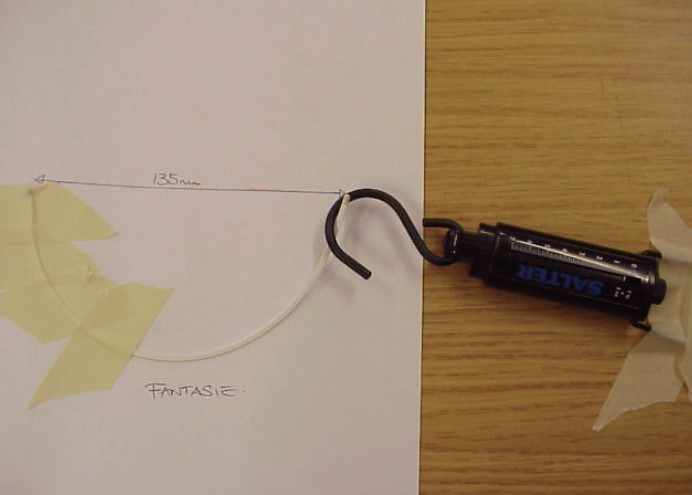

- Spring Tension: The tension, or “spring,” in the wire plays a crucial role in creating the space for the breast within the underband stretch “ring.” Testing the wire’s spring can be done using a simple spring balance. In the below photo, we can observe a 34B wire with a commercial open width of 123 mm being stretched to 135 mm. It corresponds to the average width of the 34B breast root. The force measured on the spring balance that opens the wire is generated by the tension exerted when wearing the bra with the wings securely fastened.

- Impact of Bra Size: If the bra size is too small, the wires will be sprung too wide. While a size too big may fail to open the wires adequately.

- Understanding Bra Pattern Design: When designing a bra pattern, it is crucial to ensure a proper fit when stretched onto the body frame. For instance, a 34B bra is designed with an underband length of 64 cm to accommodate a ribcage measurement of 75 cm for a size 34.

- Influence of Wing Fabric: The choice of wing fabric, whether firm stretch or soft stretch, can significantly impact wearer comfort. A firmer wing fabric tends to squeeze the wearer’s body more, potentially affecting wire positioning and comfort.

EXPLORING BRA WIRE SYSTEMS

- Euro Metric System (15 mm): This system describes the increase in wire length per size. It allows for integration into 50 mm (Imperial) or 40 mm (Euro) underband sizing.

- American System (19 mm): With a slightly larger increase in wire length per size, this system is suitable for sizes up to DD/E.

- UK Retail Core System (21 mm): Primarily used for core sizes A-D, this system offers further variations in wire length.

Armed with the invaluable knowledge of bra wire grading, you now possess the key to unlock a new era of impeccable fit and unparalleled comfort in the intimate apparel industry. So, go forth with unwavering confidence and unleash your innovative spirit to revolutionise your bra collection. Embrace the power of wiring, and let your creations radiate joy and satisfaction to all who wear them. Happy wiring, and may your journey be filled with triumph and fulfilment!