KEY TO PROFITABILITY

Costing Intimate Apparel: A Blueprint for Start-ups and Entrepreneurs

The term ‘Costing Intimate Apparel‘ refers to the process of determining the expenses associated with producing lingerie items. It involves analyzing and calculating various cost elements that can be a daunting task for many start-ups and entrepreneurs. But fear not! This article is here to help. We’ll explore the costing developments, provide examples, explain variances, and share insights from industry experts. So, before confidently quoting your price, let’s dive in and enhance your pricing decisions!

RAW MATERIALS: THE FIRST HURDLE

Picture this: you’re starting your intimate apparel brand, and you need to source materials. Sounds simple, right? Well, it can be a bit complicated. Sometimes, getting larger quantities of fabric and components can be a challenge due to minimum order requirements (MOQ). Consider exploring creative solutions like pooling orders with other brands or even using alternative materials to meet those minimums without breaking the bank. Keep it simple, focus on a specific fabric, color, and limited range of components, and let your design expertise shine!

MATERIAL UTILISATION AND LAY PLANNING

Material utilization plays a significant role in costing intimate apparel. Typically, around 85% of purchased materials end up in the final product, with the remaining 15% becoming waste. Therefore, optimizing lay planning becomes critical. Factors such as usable fabric width and damaged ends in smaller rolls can affect cutting efficiency. Careful examination of fabric quality and length upon delivery is essential.

To plan the cutting layout efficiently, consider factors like grain lines, print/pattern directions, and usable fabric area. Computerized systems like Lectra Diamino or Gerber cutters can aid in creating cutting markers, optimizing material usage, and minimizing wastage. By achieving even a 1% improvement in material utilization, you can make a significant impact on costs.

LARGE ORDER MARKERS

Scaling up from a single unit to a commercial order presents a more complex challenge. Accuracy and wastage become critical considerations. Mixed markers, which offer the best fabric utilization, are commonly used for asymmetric garments. Computerized marker-making systems provide advantages like easy pattern repositioning, automatic efficiency calculations, and elimination of paper markers.

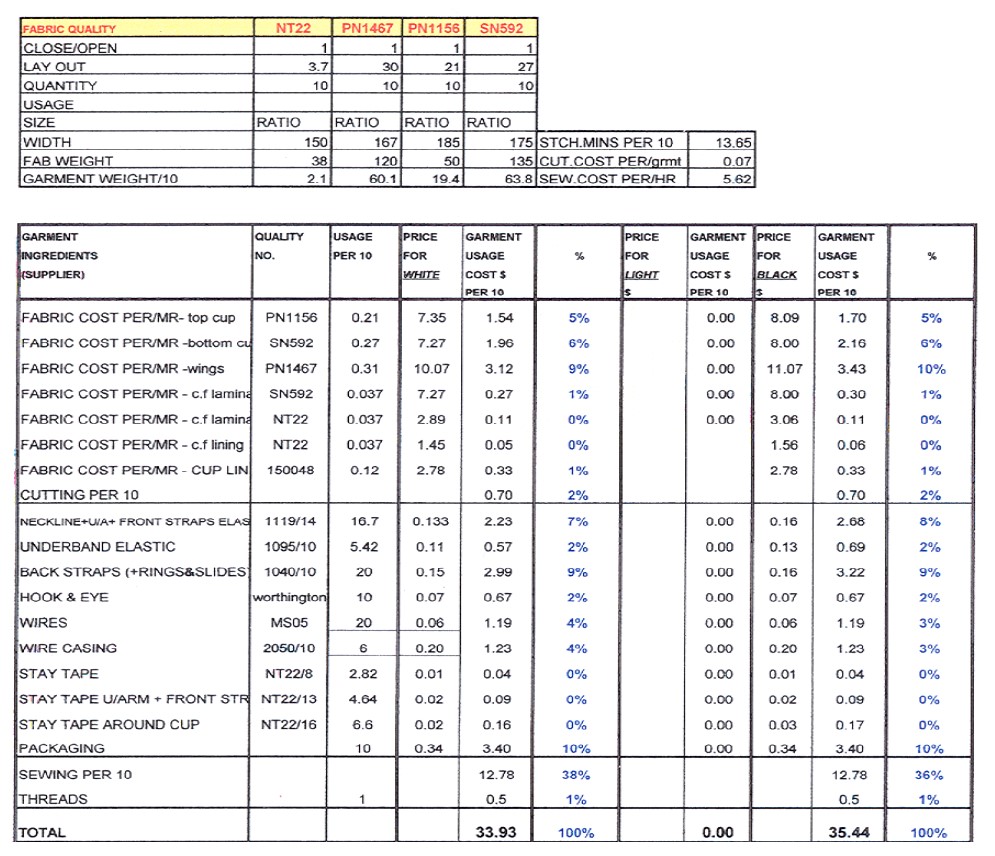

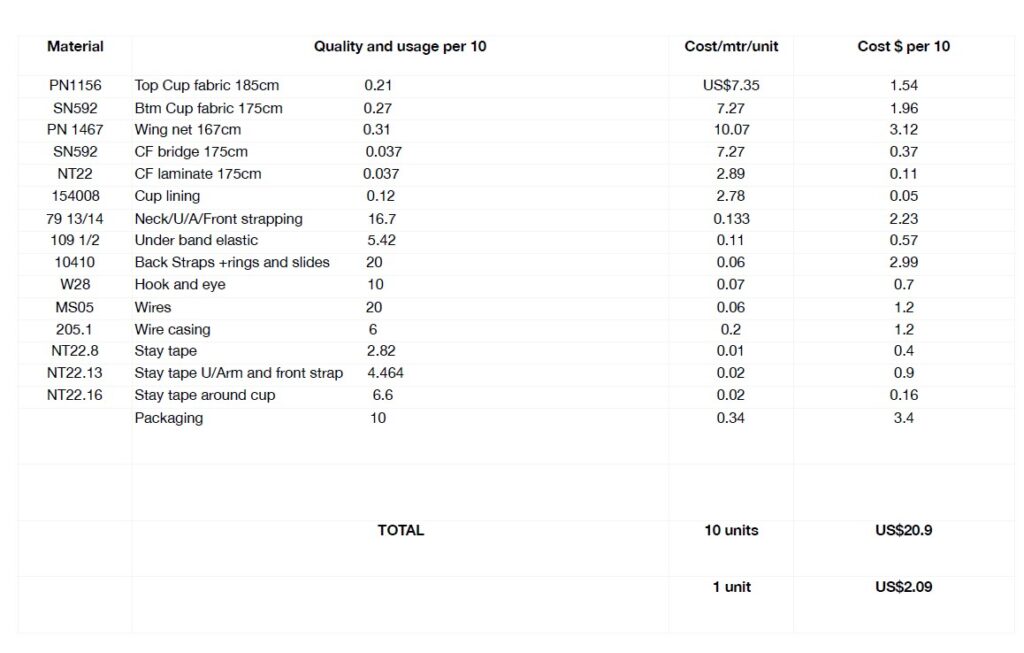

COST SHEET AND MARGINS

The cost sheet is a vital tool for understanding the factors that contribute to the total cost of each bra. It includes the Bill of Materials (BOM) for different colorways and the proportionate cost of each component or process. The cost sheet helps in calculating the margins and determining the profitability of each product.

WORK STUDY AND STANDARD MINUTE VALUE (SMV)

In most lingerie factories, sewing staff are paid based on a piece rate system, where efficiency directly influences earnings. The Standard Minute Value (SMV) measures the time required for a qualified worker to perform a specific task. Accurate SMV calculations are crucial for production planning, line balancing, and determining operator performance and factory efficiency. Work study officers measure SMV through repeated observations, which are then converted into payment values or piece rates.

FACTORY CAPACITY AND COMMERCIAL PURCHASE ORDERS

When optimising production, factory capacity plays a crucial role. Daily production capacity is determined by considering factors such as factory hours, product SMV, and line efficiency. It’s important to note that factories typically operate at less than 100% efficiency, so realistic efficiency rates should be taken into account for effective resource allocation.

Additionally, commercial purchase orders for lingerie can present complex requirements, including size, colour, and buying ratios. The preferred buying ratio can have a significant impact on profitability, especially with large band and cup sizes. Careful consideration of these factors, along with material efficiency, is essential to ensure both profitability and customer satisfaction.

INSURANCE AND SHIPPING

Before dispatching your goods, it’s essential to discuss and agree on the matter with your supplier. Depending on the terms, different responsibilities come into play. In the case of ‘Ex-factory,’ the customer takes responsibility beyond the factory gate, while FOB places the responsibility on the factory until the goods reach the dockside or airport. Another term to consider is DAP, delivered at place, where the factory remains responsible until the goods are delivered to the customer’s designated location. Remember to clarify these details for a smooth shipping process.

Costing intimate apparel is a multifaceted process requiring attention to detail, creative problem-solving, and efficient resource allocation. Considerations may vary based on factors like company size, location, manufacturing methods, and market dynamics. By equipping yourself with the knowledge and insights shared in this article, you are better prepared to navigate the intricacies of costing and make informed pricing decisions. Let’s embrace the challenges, explore possibilities, and embark on your journey to successful cost determination. Happy costing!