FIT. FABULOUS. SWIM.

Demystifying Swimwear Fabric Properties for Entrepreneurs in Intimate Apparel

Swimwear is not just about fashion and style; it’s about comfort, durability, and performance. As an entrepreneur venturing into the intimate apparel industry, understanding the properties of swimwear fabric is essential. In this comprehensive guide, we will explore the essential aspects of swimwear fabric properties, enabling you to make informed decisions while creating high-quality swimwear designs. So, let’s dive in!

SWIMWEAR FABRIC BASICS

Most swimwear fabrics are circular knitted on a circular frame knitting machine before being cut into flat lengths. A key characteristic for identifying swimwear fabric quality is its weight per square metre. Typically, high-fashion swimwear garments have 0-2% vertical ease and 12-15% horizontal ease, based on a 180g/m² two-way stretch Nylon/Lycra fabric.

FABRIC COMPOSITION

The majority of commercial swimwear is made from an approximate 80% Nylon (Polyamide) and 20% Elastane blend, known as Lycra or Spandex in the US. This two-way stretch warp knit fabric allows for optimal movement and fit. The fabric should have a maximum stretch of 50-100% in at least one direction, ensuring comfort and flexibility for the wearer.

KEY FABRIC PROPERTIES

- Weight per Square Metre: This measurement provides a general indication of the fabric’s density and, to some extent, its durability.

- Chlorine and UV Resistance: Swimwear fabrics are resistant to chlorine and commonly uses to maintain pool water hygiene. Chlorine-resistant fabrics prevent colour fading and fabric degradation. Additionally, UV protection is crucial to shield the wearer from harmful ultraviolet rays, often provided through UPF ratings integrated into the fabric.

- Quick-Drying and Breathability: A desirable swimwear fabric should have quick-drying properties to facilitate moisture evaporation. Breathability is another valuable characteristic, allowing air circulation and ensuring the wearer remains cool and comfortable.

- Pilling and Snagging Resistance: To maintain the smooth appearance and longevity of swimwear, fabrics should resist pilling (the formation of small fibre balls on the fabric surface) and snagging caused by rough surfaces or objects.

- Chemical Resistance and Resilience: Swimwear fabrics, particularly those containing Elastane, exhibit excellent resistance to alkaloids, chlorine, seawater, and detergents. Moreover, they possess resilient properties, recovering their original shape and size after stretching.

MANUFACTURING CONSIDERATIONS

Manufacturers often vary the fibre blend and weight to achieve desired fabric properties. Fabrics with a higher Elastane content can offer greater stretch and recovery, while a heavier fabric weight provides stronger recovery tension but less stretch. Specialised swimwear fabrics, such as Eurojersey’s Sensitive, employ microfiber and a higher Elastane content (above 20%) to create lightweight, fine-textured fabrics with enhanced recovery and moisture-wicking properties.

SWIMWEAR LINING FABRICS

Nearly all swimwear is lined for modesty or to prevent transparency when wet. Lining fabrics are usually 100% Nylon or a Nylon/Lycra blend. The stretch of the lining fabric should be softer than that of the outer skin fabric to avoid tension differentials that could cause ripples on the outer layer. Adding lining fabric increases the weight and recovery tension of the garment, and care should be taken when selecting the lining material.

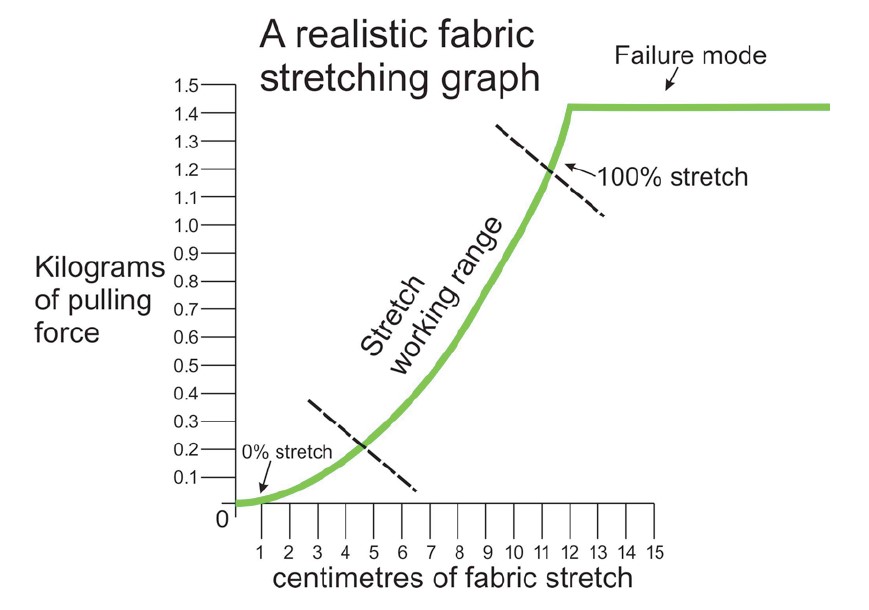

UNDERSTANDING STRETCH MODULUS

Stretch modulus allows for the comparison of different fabrics. Fabrics with high modulus provide strong control and require more force to stretch, while those with low modulus offer lighter control and require less pulling force. Fabric weight, on the other hand, is not a reliable factor when choosing and ordering stretch fabrics.

Undoubtedly mastering swimwear fabric properties is the key to creating exceptional designs that prioritise comfort, style, and durability. By understanding the composition, stretch, resistance, and manufacturing aspects, entrepreneurs can craft swimwear that surpasses expectations. With your unique vision and the magic of swimwear fabric properties, success in the intimate apparel industry awaits. Ride the wave of innovation and leave an unforgettable impression in the world of swimwear fashion!

Looking to know about swimwear elastics? Check out our blog post on swimwear elastics by clicking here.