A STEP BY STEP GUIDE

Developing a Lingerie Line

Developing a lingerie line is not as easy as it seems. It takes a lot of hard work, time and effort to create something that is both beautiful and functional. Here is a look at the process of developing a lingerie line, step by step.

To start the product development process, you first need to have finalized your designs and sourced the materials you will need. This includes finding the right fabrics and suppliers for each component. After this is ready you can proceed to bringing to life the designs into tangible garments.

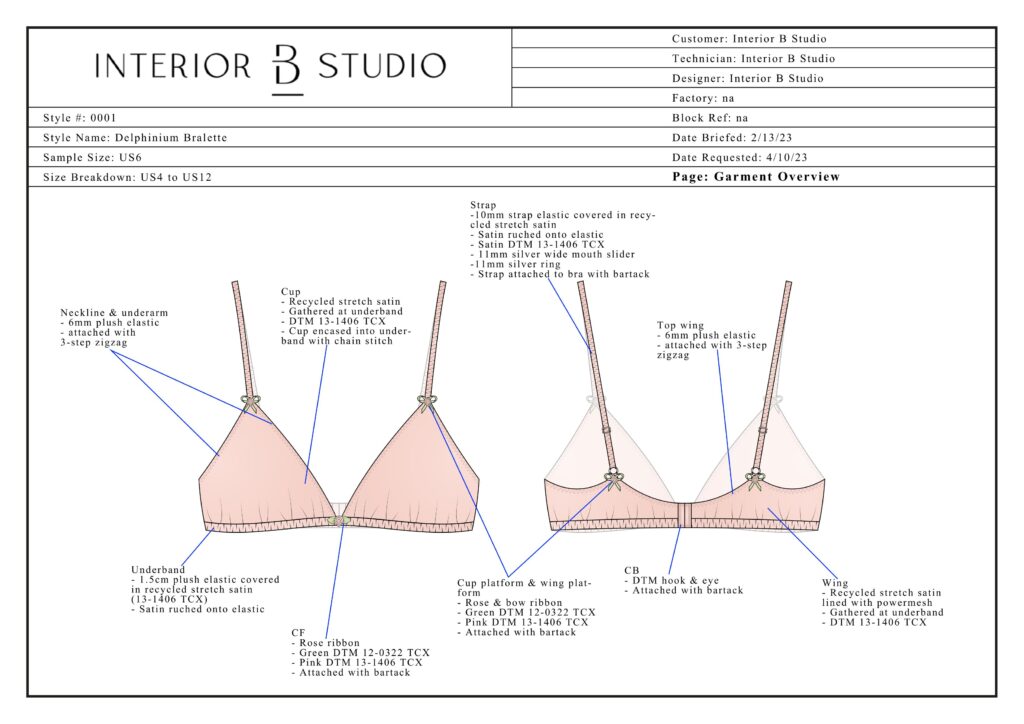

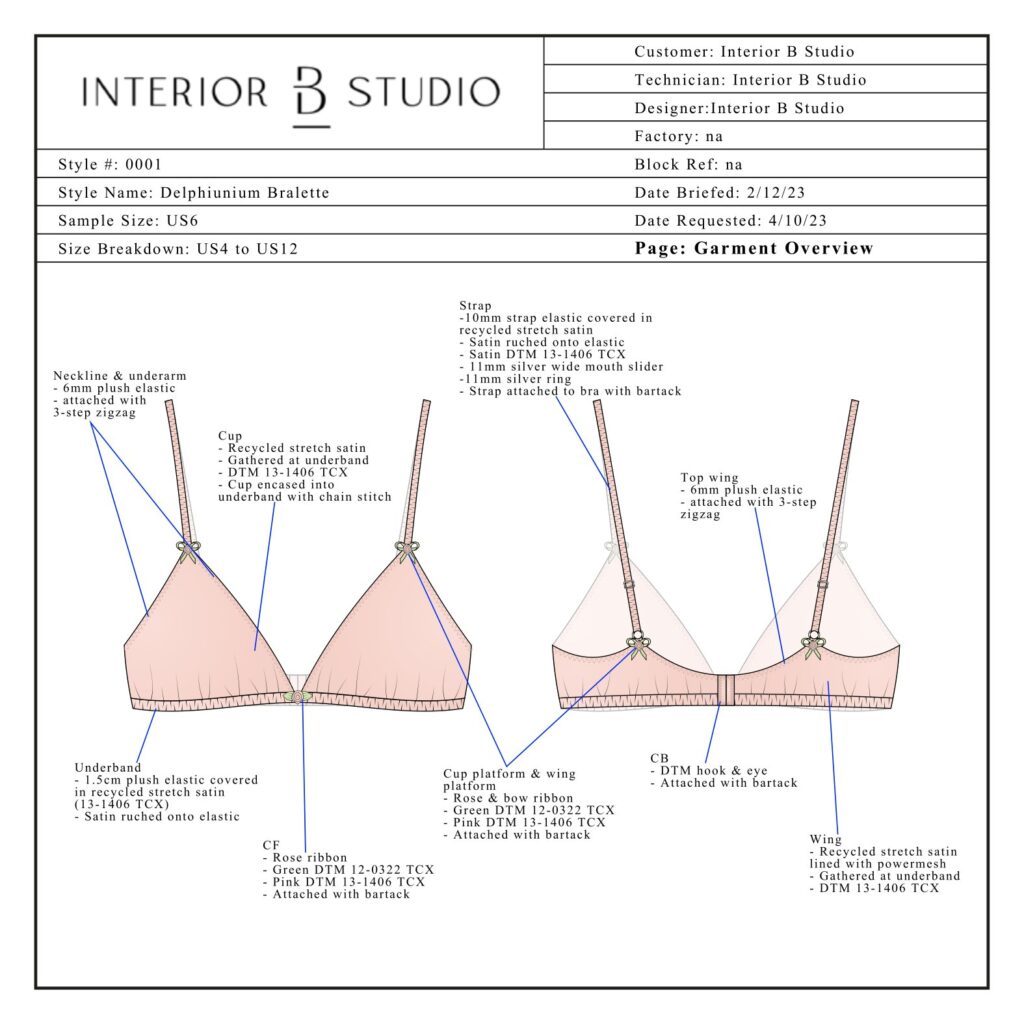

The first step in product development is creating a tech pack. This document will outline all of the specifications for the lingerie line. From the type of fabric to be used to the measurements of each piece. Nailing down all details before production begins is essential. Because any changes made later on can be costly and time-consuming.

After finalizing the development tech pack, the team must create, fit, and test samples for quality control purposes. It’s very important to have a good sample room or skilled factory specialized in lingerie when you are creating your initial samples or prototypes. This will ensure that the quality of your product is up to par. And that the sample is a good starting point to begin the fit assessment process. This is crucial for the product development cycle.

To make sure the product is good when it goes into production, you need a qualified technician. The person needs to specialize in intimate apparel. They must be able to assist you in fitting and correcting the prototype as many rounds as necessary to prepare the sample for bulk production and obtain fit approval.

The garment technician should also experience in communicating to factories how to make these changes and provide them with revised specs (specifications).

It is important to understand and know from the beginning that it can take 3-4 rounds of fittings before the garments are approved and ready to go to production. That’s why the process is very time consuming and you may need very specialized people in your team. It is must in order to produce high quality and good fit lingerie, which can make the process very costly.

Once the authorities approve the garments, they will initiate bulk production. This process typically takes a few weeks, depending on the order’s size. After producing the garments, it becomes imperative to conduct a quality control inspection (QC) to ensure that everything adheres to the specifications and maintains perfect quality. (We discuss the quality control process in this article, so you can understand better how it’s done and what you need). After completing QC, the factory will ship your order to your doorstep or warehouse, ready for sale!

With this process in mind, you will realize it is important to plan ahead, that way, you can save money and avoid mistakes. Make sure you have a good plan in place before starting production. It can look like a daunting process. But if done correctly it will result in high-quality products that your customers will love.