FINISHING TOUCHES

Enhancing Intimate Apparel through Innovative Fabric Finishing Techniques

Hey there, fellow entrepreneurs and dreamers in the Intimate Apparel scene! Let’s talk about something truly fascinating – fabric finishing. It’s the art of turning basic textiles into top-notch, functional, and super attractive garments. Whether it’s through the magic of chemistry or the finesse of mechanical techniques, fabric finishing has opened doors to multifunctional textiles with unique properties. This article delves into the world of fabric finishing, exploring its chemical and mechanical facets, and its implications for start-ups and entrepreneurs in the lingerie business.

CHEMICAL FINISHING

- Antimicrobial and Antiodor Properties: Imagine intimate apparel that remains fresh and free from unwanted bacteria, preventing unpleasant odors, decay, and discoloration. Chemical finishing techniques, such as the use of antimicrobial agents like organosilicons, phenols, and quaternary ammonium salts, have made this possible. For instance, SILVADUR™ antimicrobial technology from the Dow Chemical Company has introduced long-lasting freshness and reliable protection against undesirable microbes. Silver nanoparticles, with their large surface area, enhance the effectiveness of these agents against bacteria and fungi.

However, it’s crucial to note that while laboratory tests might showcase these properties, real-world effectiveness can vary. Factors like sweat and proteins from the human body can affect the fabric’s antimicrobial properties. Therefore, in vivo testing is needed during lingerie product development to ensure that the promised benefits hold true.

- Elastomeric Finishes: Elastomeric finishes, achieved through silicone-based products, introduce durable elasticity and deformation recovery to intimate apparel. The versatility of these finishes makes them ideal for swimwear, lingerie, and athletic wear. They enhance the softness, crease recovery, and abrasion resistance of fabrics, elevating both the comfort and longevity of your creations.

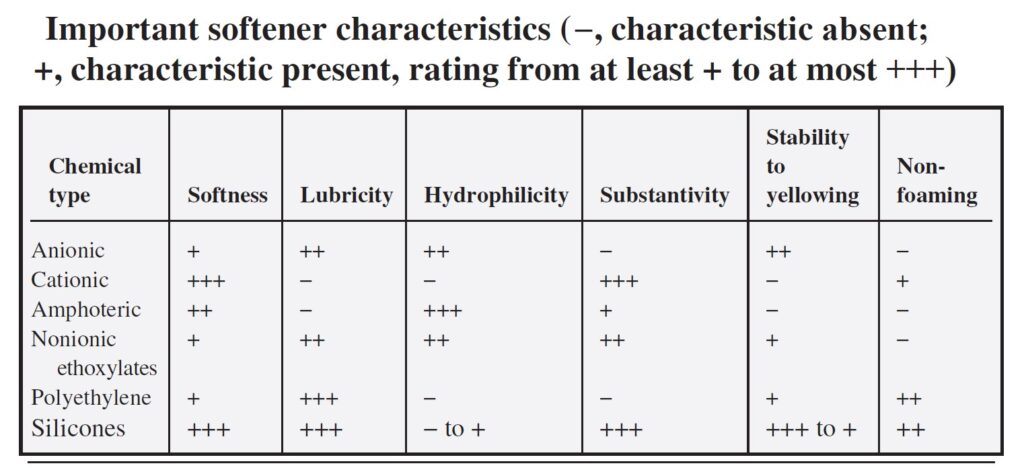

- Softening Finishes: Intimate apparel isn’t just about looking good; it’s about feeling good too, right? That’s where softening finishes swoop in. Softening finishes step in to deliver the desired softness, flexibility, and smoothness. The quest for softness is often hindered by finishing processes that strip natural oils and waxes from fibers, rendering them stiffer.

Cationic softeners have proven to be champions in this realm, offering lasting softness even after multiple launderings. However, considerations like grime attraction and dye compatibility warrant attention. Anionic and amphoteric softeners also have their place, offering unique advantages such as heat stability and antistatic effects.

MECHANICAL FINISHING

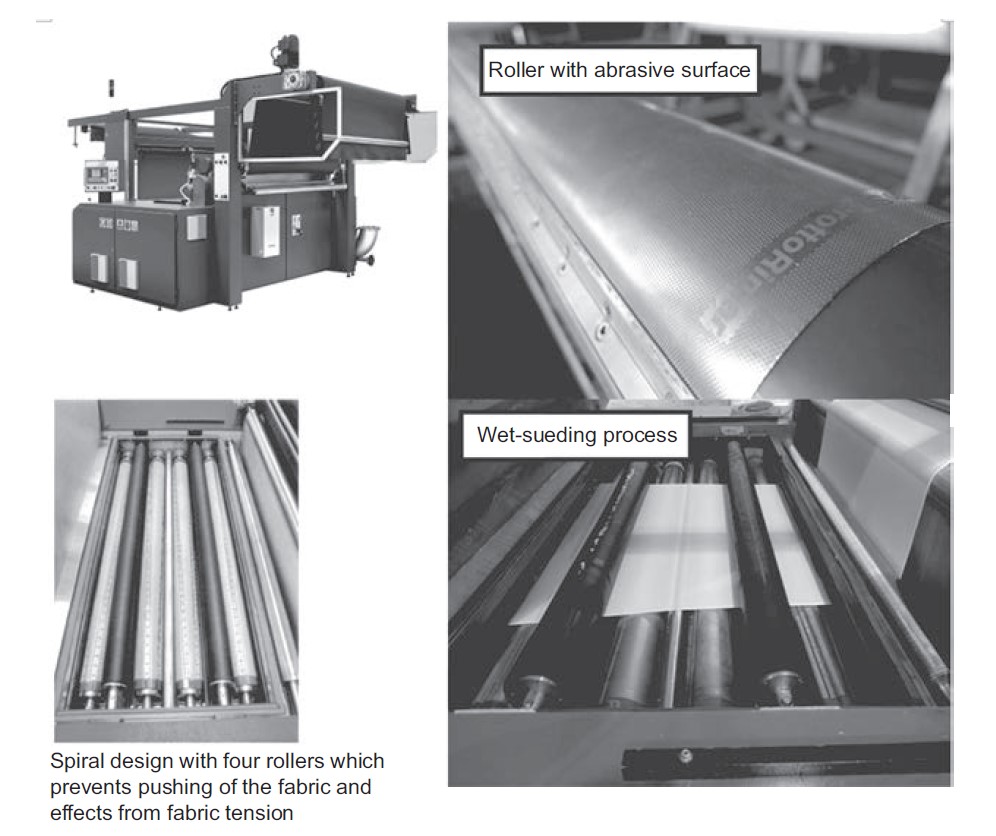

While chemical finishing focuses on enhancing functionality, mechanical finishing is all about perfecting the tactile experience. Tricot and jersey fabrics commonly used in intimate apparel can be transformed through processes like wet sueding. The Plurima machines from the Santex Group are instrumental in this technique. The process involves upper rollers pressing the fabric onto abrasive bottom rollers while water is introduced to achieve a suede-like effect. This method imparts a soft handfeel to the fabric, enhancing its appeal.

However, it’s important to note that repeated wet sueding can compromise fabric stretch and recovery. Therefore, while the technique offers a luxurious handfeel, its long-term effects should be considered in the design and manufacturing process.

Fabric finishing in the intimate apparel industry is a story of innovation, functionality, and constant evolution. By harnessing the power of chemical and mechanical finishes, start-ups and entrepreneurs can pave the way for fabrics that not only adorn bodies but also enrich lives. As the journey unfolds, the fusion of creativity and technology promises a future where intimate apparel isn’t just worn – it’s experienced.