FULL PACKAGE PRODUCTION

Everything You Need to Know about FPP Manufacturing for Intimate Apparel

If you’re a start-up or entrepreneur in the intimate apparel industry, you understand the critical importance of optimizing manufacturing processes, minimizing costs, and ensuring efficiency to achieve success. One approach that has gained significant traction is FPP Manufacturing, which stands for Full Package Production. In this blog post, we will explore what FPP manufacturing is, how it works, and its pros and cons for intimate apparel production.

What is FPP Manufacturing?

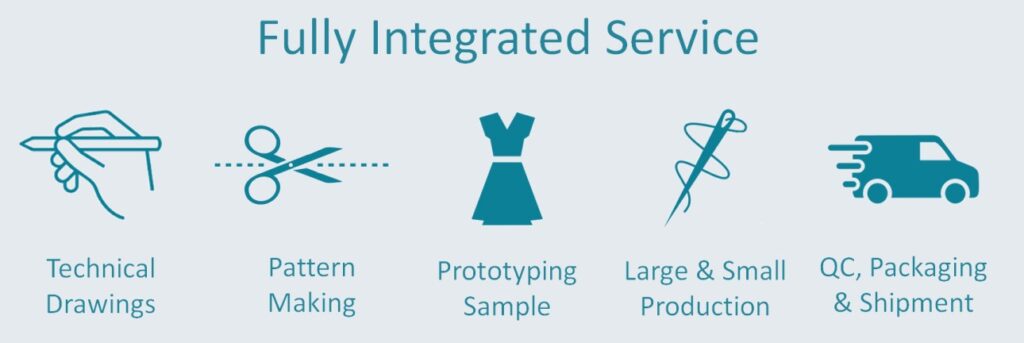

FPP manufacturing entails an all-inclusive production approach in which a manufacturer oversees every step of the process. This starts from garment design and fabric/trims sourcing to cutting, assembling, trimming, and ultimately delivering the finalized product. This method proves highly advantageous for businesses that do not have the resources or expertise to handle every aspect of the manufacturing process and need a one-stop-shop solution.

How it Works?

- Design and Development: The manufacturer collaborates with the entrepreneur to create a design that meets their vision. Fabric, trims, and materials are selected, and a sample is created for approval.

- Sourcing Materials: Once the design is approved, the manufacturer sources the fabric, trims, and other materials meeting the entrepreneur’s quality standards and specifications.

- Production: The next step is production where workforces cut the fabric, assemble the garments, and add finishing touches according to the entrepreneur’s specifications.

- Quality Control: The manufacturer conducts regular quality control checks throughout the manufacturing process. It ensures the finished product meets the entrepreneur’s quality standards.

- Shipping and Delivery: Once the manufacturing process is complete, the manufacturer ships the finished products to the entrepreneur’s desired location.

Pros and Cons of FPP Manufacturing for Intimate Apparel

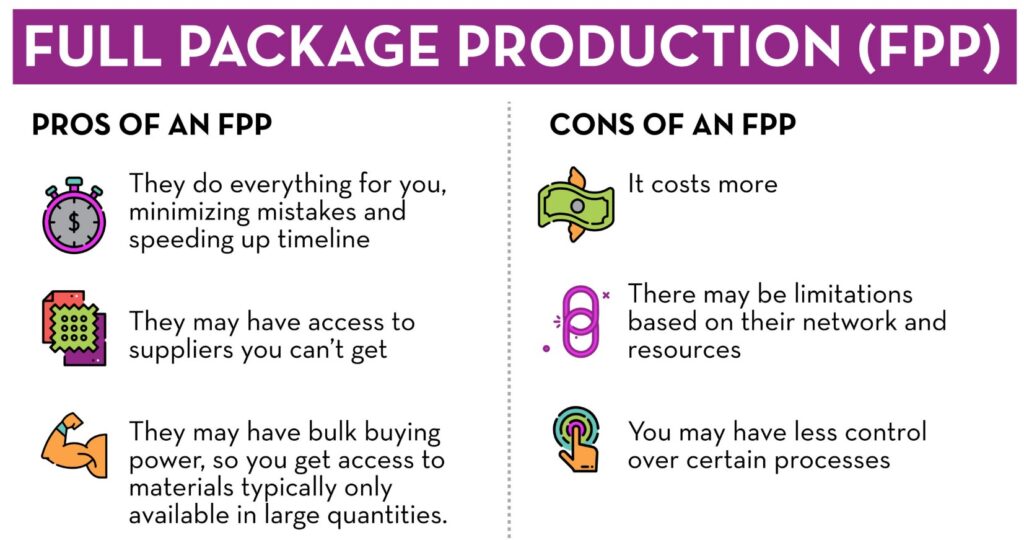

Pros:

- Streamlined Process: FPP usually covers everything from design to delivery, making it a convenient and efficient option for entrepreneurs.

- Expertise and Resources: FPP manufacturers have expert knowledge and resources in intimate apparel production, providing valuable expertise and ensuring quality control.

- Cost Efficiency: By handling the entire production process, manufacturing by FPP can optimise costs through better material sourcing and supplier relationships.

- Time Savings: Entrepreneurs can focus on other aspects of their business. The manufacturer takes care of production, saving them time and allowing them to concentrate on growth.

Cons:

- Limited Control: Entrepreneurs have less direct control over the production process, relying on the manufacturer’s expertise and systems.

- Communication Challenges: Effective communication is vital, and miscommunication or differences in interpretation can lead to design or quality issues.

- Dependency on Manufacturer: Engaging in manufacturing by FPP method creates a level of dependency on the manufacturer. This could pose challenges if issues arise or if entrepreneurs want to switch manufacturers.

- Limited Customization: FPP method offers limited flexibility for highly customized designs, as it typically follows standardized processes and options.

If you’re looking for a manufacturing process that offers convenience, time-saving benefits, and maintains high quality standards, then FPP manufacturing could be the perfect solution for you. However, it’s vital to thoroughly assess the pros and cons. It’s also important to have a clear understanding of CMT manufacturing. Before making any commitments, we recommend reading our blog post on CMT vs. FPP to gain deeper insights. Wishing your journey ahead be filled with great success and exciting opportunities!