FORM, FUNCTION, FASHION

Everything You Need to Know about Moulded Bras

Hey there, lingerie lovers and aspiring entrepreneurs! Let’s talk about moulded bras. These gems are a game-changer in the intimate apparel industry, offering comfort, support, and style like no other. So, let’s explore everything you need to know about moulded bras, from how they’re made to why they’re a must-have for your brand!

UNDERSTANDING MOULDING AND MATERIALS

- Moulding Process: Moulding is the process of transforming a piece of fabric or foam sheet into a three-dimensional shape that retains its form over time. The process entails skilfully merging heat, pressure, and dwell time in order to suit the unique characteristics of every fabric and mould shape.

- Suitable Materials: Almost every knitted fabric can be moulded, provided it contains a percentage of synthetic yarn. Whether it’s synthetic or natural fibres like cotton and silk, a high percentage of man-made fibre is desirable for its lower fixing temperature and ability to hold the moulded shape after wash and wear.

- Polyurethane Foam: Polyurethane foam is widely used in moulded cup production due to its softness, flexibility, and ability to be cut into various thicknesses. However, the production process requires careful control of pressure, temperature, and time to avoid glazing or discoloration.

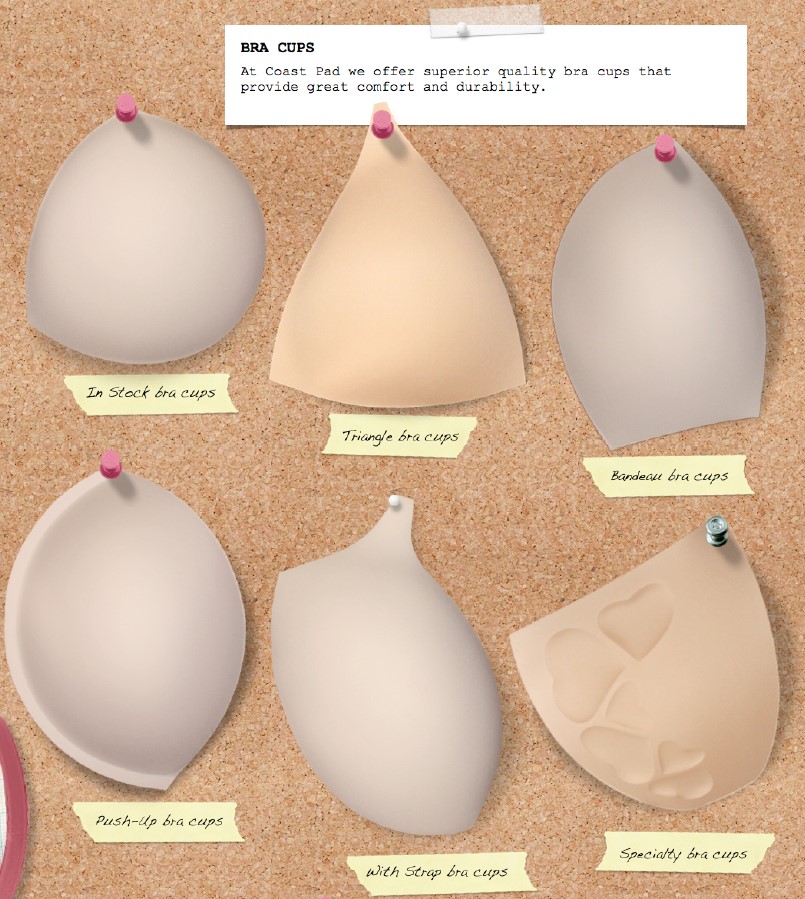

STYLES OF MOULDED BRAS

- Hard Mould Wired Bras: This popular style features moulded cups with underwires for added support. Generally it can be identified by the binding applied to cover the raw edge of the cup. Skilful manufacturing techniques result in smooth top skins and expertly finished neck edges.

- Soft Moulded Cups with or without Wires: These bras offer a softer alternative to hard moulded cups. Some versions feature a moulded top skin without a polyurethane (PU) cup inner shell, while others may include a PU mould shell or wires. These styles are gaining popularity due to their comfort and versatility.

- 3D Moulded Bras with Raised Inner Profile: These bras feature complex construction with layers of materials, such as sponge, joined by a hot-melt adhesive process. Some versions may include fillers like air bags, water, or gel bags for additional shaping and comfort.

- Bonded Moulded Bras without Wires: A modern twist on moulded bras, these styles feature a moulded top skin without conventional sewing construction. The absence of wires adds to the comfort factor, while the bonding technique creates a sleek and seamless look.

MANUFACTURING PROCESS FOR MOULDED CUPS

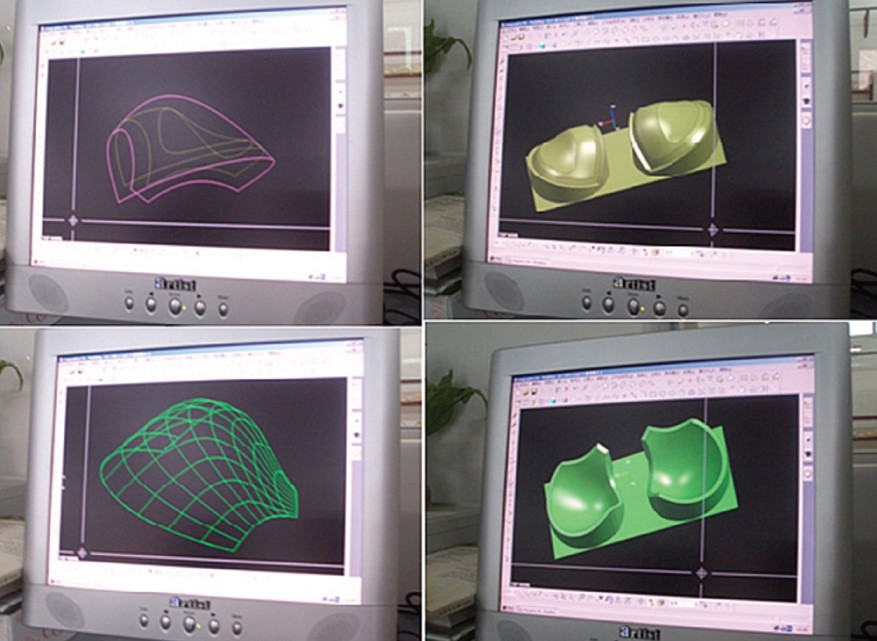

- Initial Cup Shape Development: It all starts with clay or wood. Craftsmen sculpt the perfect cup shape, envisioning the end result.

- 3D Scanning: Technology comes into play here. The sculpted cups are 3D scanned; creating a digital file that guides the next steps.

- CNC Cutting: Enter the CNC router, a cutting machine controlled by computers. It reads the digital file and cuts the moulds with precision. It’s like watching art come to life!

- Moulding Process: This is where the magic happens. The fabric is clamped to the bed, and the workforces moulds compress it to create the desired cup shape. It’s a dance of heat, pressure, and time!

- Trimming and Checking: After moulding, the cups are trimmed to perfection using a clicker press with a pre-shaped cutter.

BENEFITS FOR START-UPS AND ENTREPRENEURS

Now that you know the ins and outs of moulded bras, let’s talk business. As a start-up or aspiring entrepreneur in the intimate apparel industry, these bras can be your secret weapon for success. Here’s why:

- Fast and Controlled Production: These bras offer a streamlined production process once you have the necessary equipment and sewing skills in place. Undoubtedly this means you can efficiently meet the demand for these popular styles, ensuring a quick turnaround time for your customers.

- Versatile Styles: With moulded bras, you have a world of options at your fingertips. Whether it’s a hard mould wired bra for optimal support, soft moulded cups for ultimate comfort, or 3D moulded bras for that wow factor, you can cater to diverse customer preferences.

- Unmatched Comfort and Support: These bras are designed to provide exceptional comfort and support. Basically the pre-formed cups and optional underwires ensure a perfect fit, offering all-day comfort without compromising on style. Your customers will thank you for the comfort boost!

In summary, these bras offer a winning combination of fast production, versatile styles, and unbeatable comfort and support. By incorporating these gems into your product line-up, you’ll be well-positioned to make a splash in the intimate apparel industry. Obviously it’s time to unleash the power of moulded bras and watch your business soar!