KNIT TO FIT

Exploring Knitting Parameters in the Intimate Apparel Industry

Step into a world where innovation in intimate apparel becomes an exquisite dance between creative threads and the mastery of cosiness. Did you know that when it comes to knitting, there are quite a few parameters that can change how a piece of lingerie looks and feels? We’re talking about stuff like the way the stitches are done, how the loops are formed, the type of yarn used, the settings on the knitting machine, and even the design process itself. All these things team up to give a garment its unique appearance, how strong it is, and how comfy it feels when you touch it.

KNITTING PARAMETERS

Stitch Types: Crafting Artistry

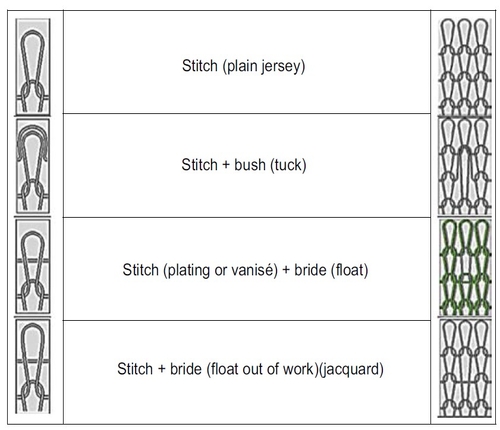

Knitting begins with stitch types, forming the foundation of your garment’s design. Weft knitting structures employ various stitches, from plain stitches to miss stitches and tuck stitches. Circular knitting machines create a shape by blending different knitting structures and loop lengths. Plain plating, for instance, involves combining different yarns to achieve specific fabric effects. Float plating, tuck stitches, and jacquard plating can also be achieved through the precise programming of the needle selection mechanism.

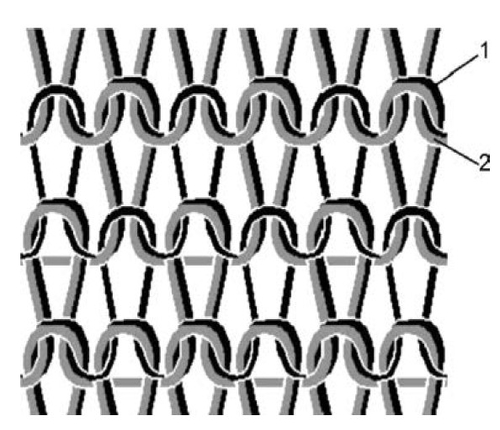

Loop Formation: Engineering Elegance

Loop formation is an art that involves latch needles and sinkers working in harmony. Holding-down sinkers guide the cylinder needles, ensuring precision. Understanding the mechanics behind loop formation is key to achieving the desired fabric properties. From the initial latch opening to the final stitch creation, the interplay of needles and sinkers contributes to the fabric’s structure and feel.

1. Ground Yarn & 2. Plated Yarn

Yarn Types: The Thread of Innovation

The choice of yarn is the heart of any knitted garment. The Intimate Apparel industry embraces an array of yarns – from natural to synthetic elastic fibers. The selection depends on factors like appearance, fabric properties, and comfort. Microfibers, especially polyamide microfibers, have revolutionized the seamless underwear market, offering breathability, rapid drying, and durability. Combining fibers like polyester and cotton satisfies traditional consumers, while elastomeric fibers like spandex amplify elasticity for a snug fit.

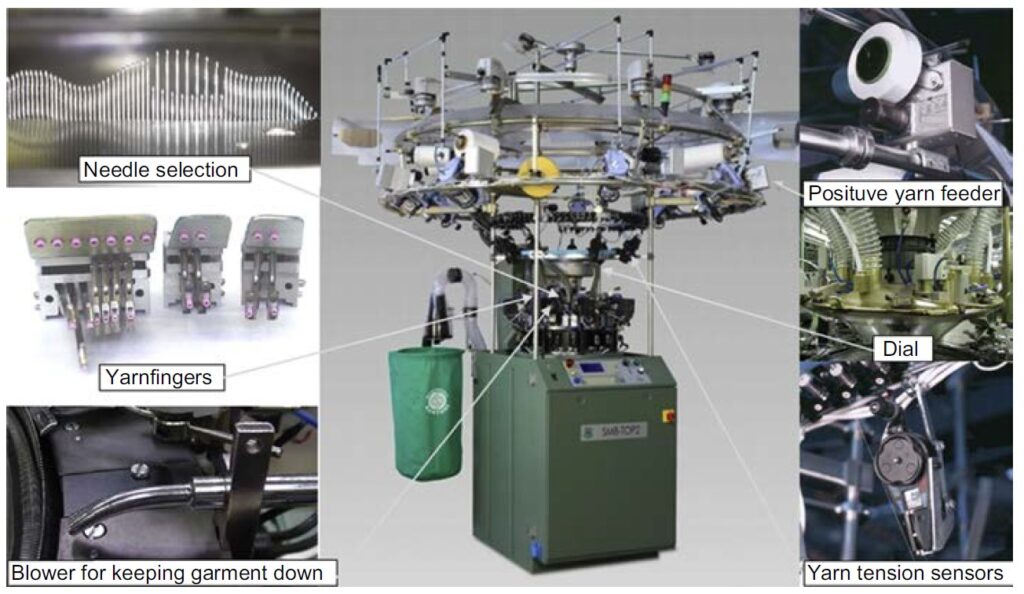

Machine Settings: Precision Engineering

Fine-tuning machine settings is a science that requires attention to detail. Adjusting yarn tension and running speed for each yarn feed ensures consistent quality. Mechanical energy is harnessed to measure loop lengths and garment dimensions. Constant-tension devices and feed control systems play their roles in maintaining uniform knitting tension, ensuring that the needles draw the right amount of yarn based on the machine’s configuration.

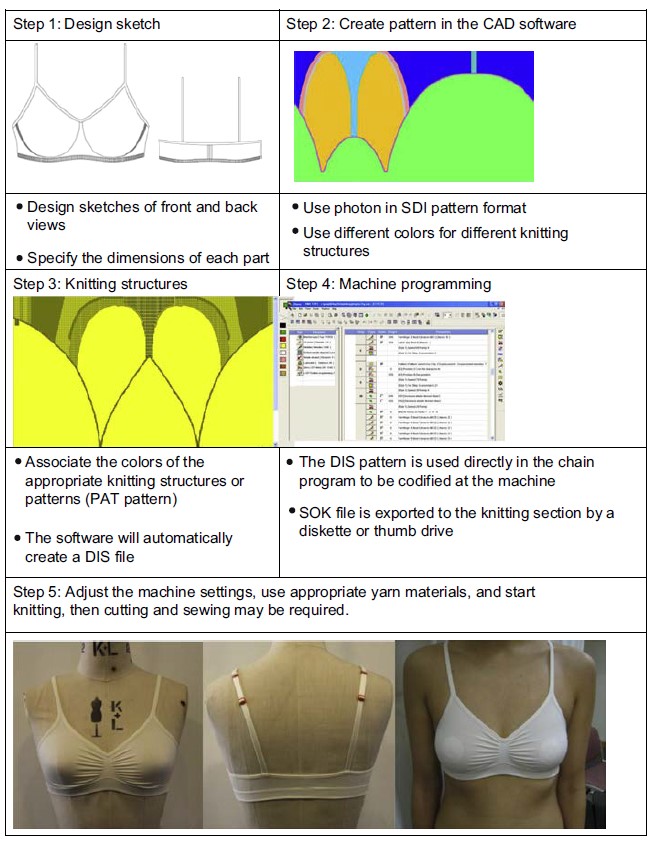

Design Process: From Imagination to Reality

The transition from virtual design to knitted reality involves CAD programming. Software like Graph6 CAD and 3D knitting software streamline the process, transforming ideas into seamless, comfortable garments. With fewer procedures and enhanced fibre and yarn compatibility, this process exemplifies the marriage of technology and creativity.

Finishing Process: Crafting the Final Touch

Knitting sets the stage, but the finishing process elevates the garment. Scouring, heat-setting, dyeing, and pressing refine the fabric. Heat-setting stabilises the garment size and enhances its handfeel. Boarding, the process of shaping the fabric using heat and steam, ensures the final product meets the envisioned design.

Quality Control: Precision in Every Stitch

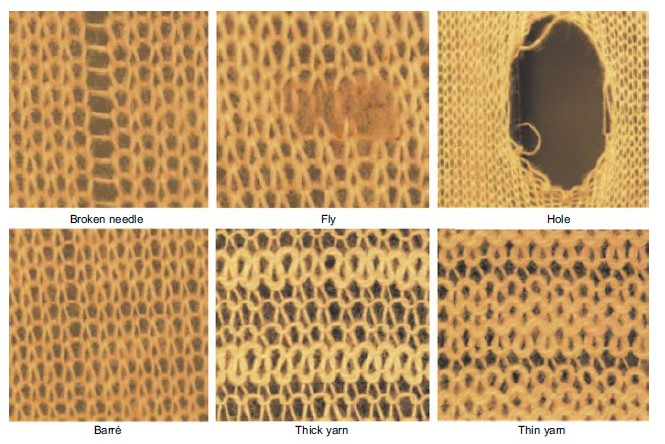

Ensuring consistent quality is a challenge in the elastic world of circular-knitted garment tubes. Tensile tests gauge extension and identify disparities, indicating the need for adjustments. Quality control also addresses knitting defects such as broken needles, holes, and inconsistencies. With meticulous attention, garments emerge flawless.

Knowledge Gap: Forging Ahead

As the industry evolves, so do its challenges. Seamless knitted bras have revolutionized comfort but grapple with breast compression issues. Bridging the gap between knitting parameters, garment behaviour, and fit perception is a fertile area for research. To realise the potential of seamless knitting, a new design paradigm is essential.

Knitting parameters are the building blocks of innovation in the lingerie industry. Understanding the nuances of stitch types, loop formation, yarn selection, machine settings, design processes, and quality control will empower you to create garments that are not only visually appealing but also comfortable and durable. As a start-up or entrepreneur in this competitive industry, embracing these parameters will undoubtedly enable you to craft intimate apparel that sets new standards of excellence. Happy knitting!