TEST FOR SUCCESS

Fabric Stretching Tests: The Key to Quality Intimate Apparel Products

You’re in the business of intimate apparel, which means that quality is top priority to succeed. To create the perfect product, fabric stretching tests are one of the most crucial steps you need to take. These mechanical tests can provide critical information about a fabric’s stretch and recovery properties, ensuring that the finished product meets customers’ expectations significantly. In this article, we’ll guide you through fabric stretching tests, including how to conduct them, available test types, and how to interpret the results.

Fabric stretching tests are mechanical tests that measure a material’s stretching force to a specific length. These tests are essential in the textile industry, especially in intimate apparel, as they provide critical information on a fabric’s stretch and recovery properties.

The Purpose of Stretching Tests for Fabric

The purpose of fabric stretching tests is to determine the maximum force a fabric can withstand before it fails or stretches beyond its intended limits. These tests are markedly performed to ensure that the fabric used in the production of intimate apparel meets the specific requirements for stretch, recovery, and durability.

Types of Stretching Tests for Fabric

Certainly there are several types of fabric stretching tests, including load-elongation tests, compression tests, and recovery tests. The load-elongation test is the most common test used in the intimate apparel industry.

Load-elongation Test

The load-elongation test measures the force required to stretch a fabric to a given length. It is conducted by clamping a sample of the fabric to two jaws of a testing machine and applying a load in a specific direction until the sample stretches to a predetermined length. The amount of force required to reach the target length is recorded. The process is repeated in the opposite direction to obtain data for both stretch and recovery.

Compression Test

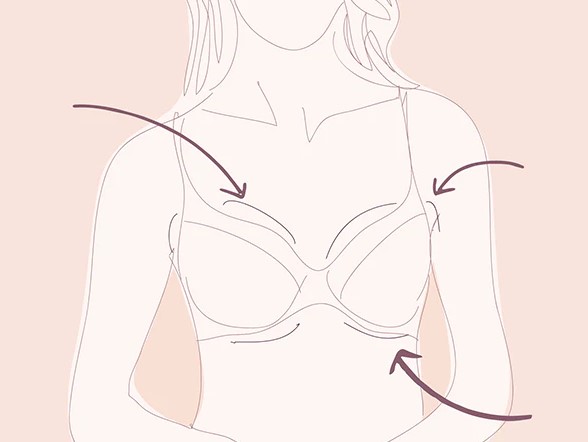

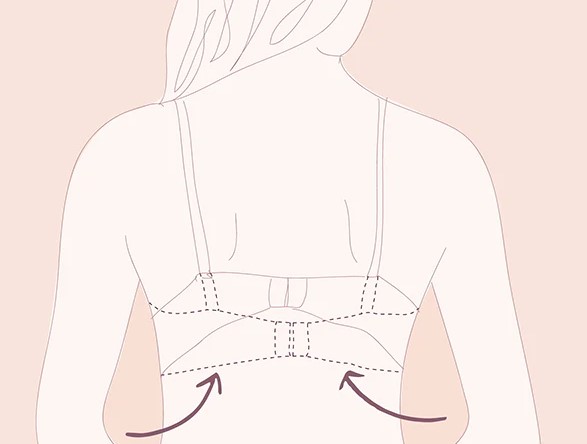

The compression test measures the force required to compress a fabric. This test is essential for materials used in bras and other intimate apparel items that need to maintain their shape and support.

Recovery Test

The recovery test measures the ability of a fabric to return to its original length after being stretched. It is conducted by stretching a fabric sample to a specific length and then releasing the tension. The percentage of the fabric’s original length that it returns to is recorded.

Conducting Stretching Test for a Fabric

To conduct a fabric stretching test, you will basically need a testing machine, a sample of the fabric, and a testing protocol. Firstly the sample should be cut to the appropriate size and shape, depending on the test being performed. It is important to ensure that the sample is free of wrinkles, folds, or other defects that could affect the test results surprisingly.

Interpretation of Results

The results of fabric stretching tests are typically presented in load-elongation graphs. The graphs show the amount of force required to stretch a fabric sample to a specific length. These graphs can help identify quality issues such as low elasticity or poor recovery, which could lead to a garment that does not fit properly or loses its shape over time.

Fabric stretching tests can also identify areas for improvement in the manufacturing process. By conducting these tests, start-ups and entrepreneurs can ensure that their intimate apparel meets customer expectations for quality and durability. With this knowledge, undoubtedly they can improve their products, use better materials, and refine their manufacturing processes to meet market demands and increase customer satisfaction.

Want to know more. Check out the blog posts on: