CREATE LINGERIE THAT FITS

Grading Intimate Apparel: A Guide for Start-ups and Entrepreneurs

Grading is an essential process in the intimate apparel industry to turn a pattern for a garment of one size into other garment sizes, while keeping the original style and function of the designer’s prototype garment. The process of grading involves multiplying any faults in the sample size pattern. So it is crucial to have a well-fitted prototype. The size range for a garment can vary, including dress sizes, band sizes, and cup sizes, making the grading process a challenging task for lingerie manufacturers.

Despite this challenge, the intimate apparel industry offers products to millions of customers who often have no idea what size lingerie they should buy. In this article, we will provide a general guide to grading intimate apparel for start-ups and entrepreneurs in the industry.

GRADING BASICS FOR INTIMATE APPAREL

- Grading is the process of creating patterns in different sizes from a single master pattern.

- In intimate apparel, grading is essential to create garments that fit a wide range of body shapes and sizes.

- To grade a pattern, developer take a set of measurements from a sample size. Then, the developer apply a mathematical formula to adjust those measurements proportionally and create other sizes.

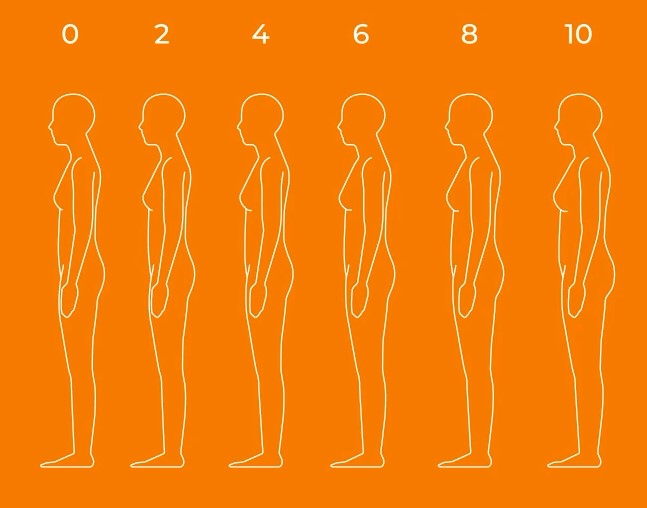

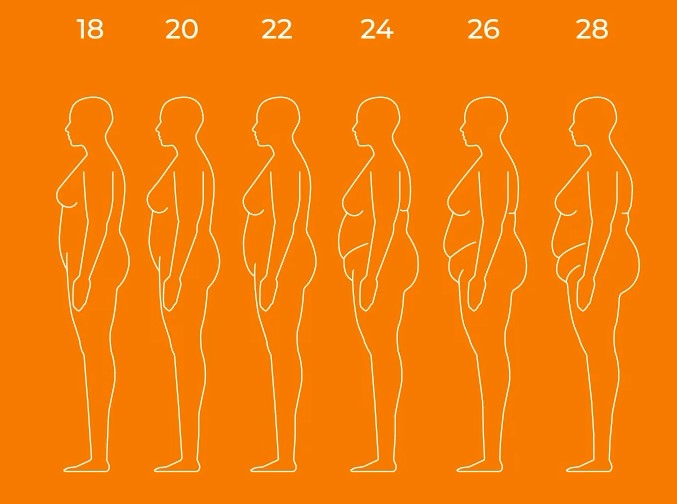

- Common size range options include body sizes (e.g., 6-8-10-12-14-16-18-20-22-24), dual sizing (e.g., 6/8-10/12-14/16-18/20), or band and cup sizes for bras (e.g., 28-30-32-34-36-38 for bands and A-B-C-D for cups).

- When grading for intimate apparel, it’s important to consider factors such as the stretch and recovery of the fabric, the desired ease and fit, and any specific design elements.

- Typically, individuals grade patterns digitally using computer-aided design (CAD) software or manually with a grading ruler or grading machine.

- Commonly, designer use a block pattern with no seam or hem allowances for grading, and then they add allowances to create a working pattern.

- After grading, it’s important to thoroughly test the fit and comfort of the graded patterns on a range of body shapes and sizes before producing the final garments.

- The accuracy of grading is essential for ensuring that each size fits well and provides the necessary support and comfort.

GRADING METHODS FOR INTIMATE APPAREL

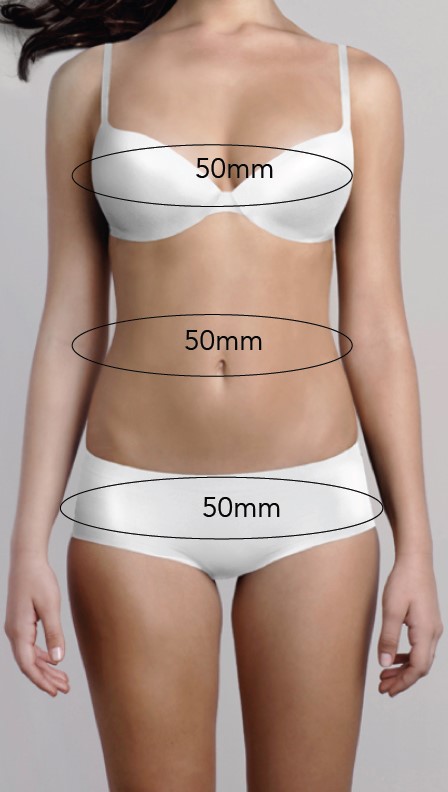

- Imperial Grading: Imperial grading, also known as 2″ or 50 mm grading. It is the most common grading system worldwide and is used for UK and USA dress sizing. It typically involves adding 50 mm or 2″ to the bust, waist, and hip measurements for each size in the size range.

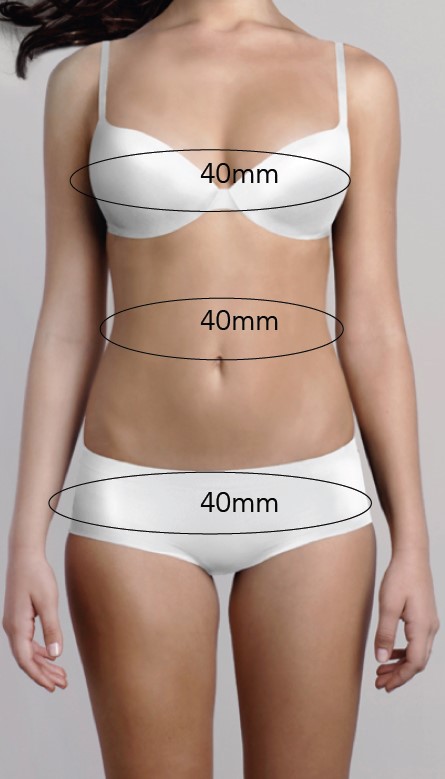

- Metric Grading: Metric grading, also known as 40 mm grading became popular in Europe in the 1970s. It is commonly used for smaller/fashion garments, swimwear, sportswear, and knickers for core sizes (e.g., 6-8-10-12-14). It involves adding 40 mm to the bust, waist, and hip measurements for each size in the size range.

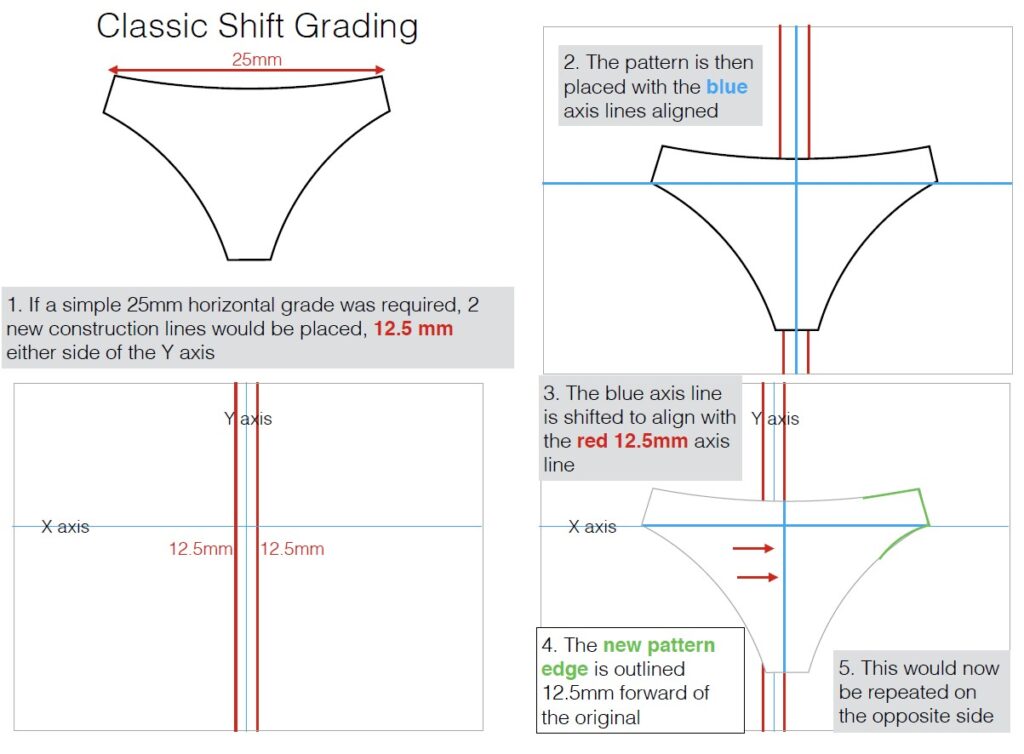

- Shift Grading: Shift grading is a method where the pattern is placed on a grading area with vertical (X) and horizontal (Y) axes. Tracing the pattern edges creates new lines for each size. This method suits simple patterns but may necessitate the use of set squares for accuracy.

Grading intimate apparel is definitely a challenging process. However, by understanding the grading process and choosing the right method, start-ups and entrepreneurs can produce intimate apparel that fits their customers’ diverse body shapes and sizes. It is important to remember that any faults in the sample size pattern will be multiplied in the grading process. So accuracy and attention to detail are critical. With this guide, we hope you will have the necessary tools to produce well-graded intimate apparel.