CASING INNOVATION

Innovations in Bra Wire Casings: A Must-Know for Intimate Apparel Entrepreneurs

Bra wire casing, also known as underwire casing, is an essential component in the construction of bras and other intimate apparel. It is a fabric channel that encases the underwire, providing support, structure, and comfort to the bra. The underwire itself is a semi-circular, flexible wire sewn into the bottom edge of the bra cup, designed to contour to the shape of the wearer’s bust and provide additional support and shaping.

In this article, we will explore various innovative solutions and patents that can revolutionize the way bra wire casings are designed and manufactured, making life easier for both the wearer and entrepreneurs in the intimate apparel industry.

TRADITIONAL BRA WIRE CASING

Before exploring into these innovations, let’s first understand the conventional bra wire casing. Typically, it consists of three layers: brushed tricot, a stabilizer, and woven fabric. This combination is designed to shield the wearer from the sharp metal underwire. However, a common issue with traditional casings is that, over time, the wire can pierce through the fabric, leading to discomfort and potential harm during laundering.

INNOVATIVE SOLUTIONS

TUBULAR FABRIC WITH FUSIBLE YARN

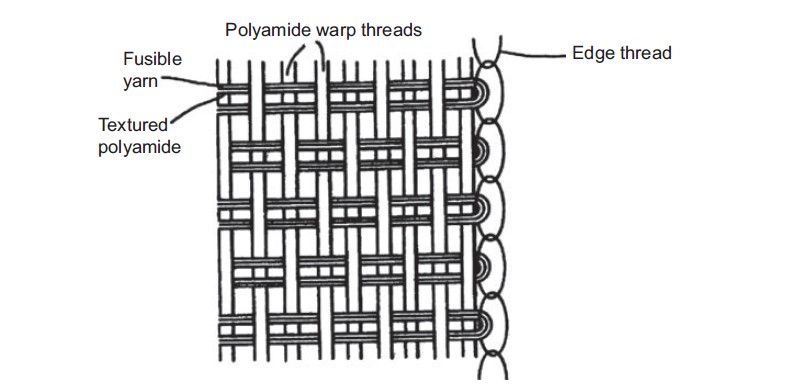

Stretchline Intellectual Properties Ltd, formerly known as Price Shepshed Ltd, introduced an ingenious solution. They invented a tubular fabric made by arranging a support yarn and a fusible yarn, like Grillon™, to create a barrier. This unique tubular construction, shown in below figure, prevents the wire from piercing through, even during the most rigorous activities. The fusible yarns, strategically placed across the width of the fabric, allow for stretchability in the lengthwise direction, ensuring a comfortable fit.

SAFETY BUBBLE CUSHION BRA-SHEATH

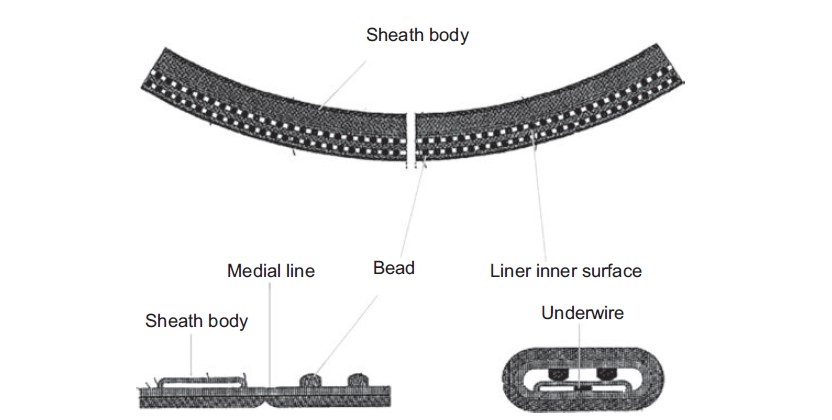

‘Four K Knitters’ factory introduced the “Safety Bubble Cushion Bra-Sheath”. This innovative bra wire casing comprises a woven fabric liner with interlocking warp and weft threads. What sets it apart is the use of heat-fusible materials within some threads. During the bonding process, these materials melt, creating a secure, wire-proof barrier. The resulting inner cavity is perfect for wire insertion, ensuring both safety and comfort for the wearer.

MARK-FREE FABRIC STRAP WIRE CASING

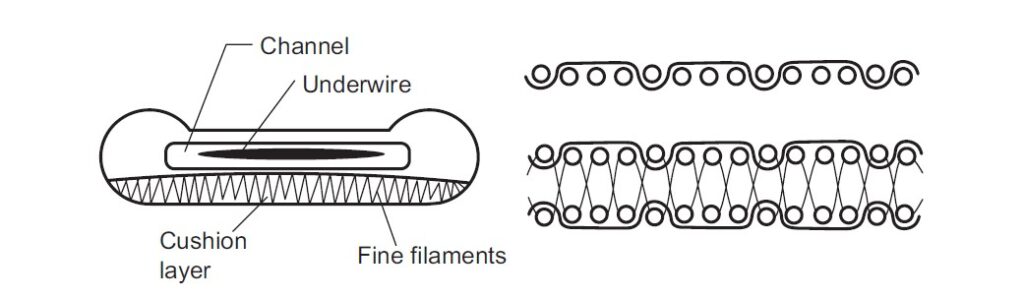

New Horizon has introduced a mark-free fabric strap wire casing. This unique design features a cushion with erect fine filaments. These filaments provide a cushioning effect that relieves the stress exerted by the bra wire on the skin. Not only does it enhance comfort, but it also ensures a mark-free experience for your customers.

GEL-CUSHIONED SUPPORT COMPONENT CHANNEL

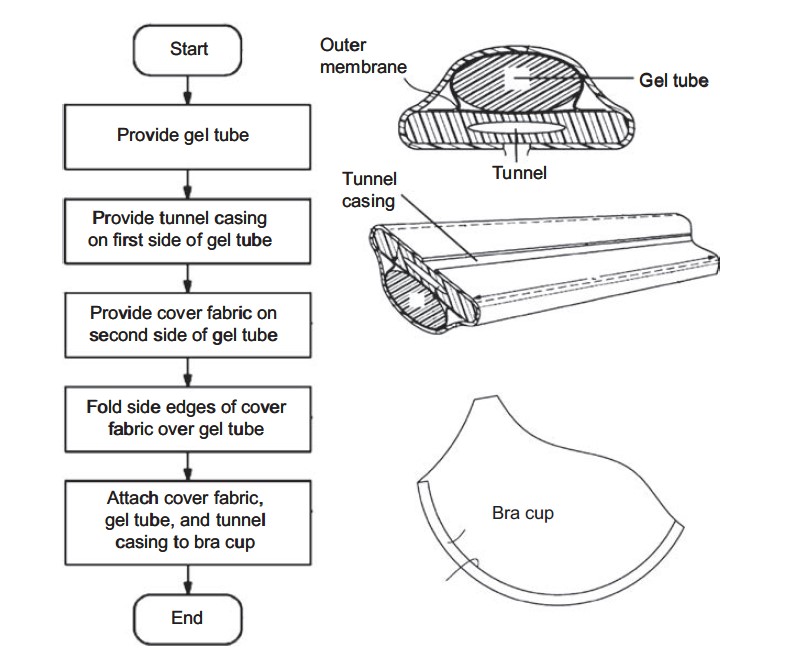

Yung et al. have introduced a “Gel-cushioned support element channel for a brassiere.” This innovative design adds gel cushioning inside the bra underwire casing. The result is a supremely comfortable and supportive experience for the wearer. This technology provides an extra layer of comfort and minimizes discomfort associated with underwire bras.

The evolution of bra wire casings, as demonstrated by these innovations, reflects the industry’s dedication to delivering superior products. Wire casings vary in material, thickness, and design, impacting bra comfort and performance. This is undeniably a crucial consideration for lingerie entrepreneurs. So, prioritize every aspect to provide valued customers with utmost comfort and confidence.