Elements of a Successful TNA Plan

Key Elements in a Time and Action Plan (TNA) for Manufacturing Apparel

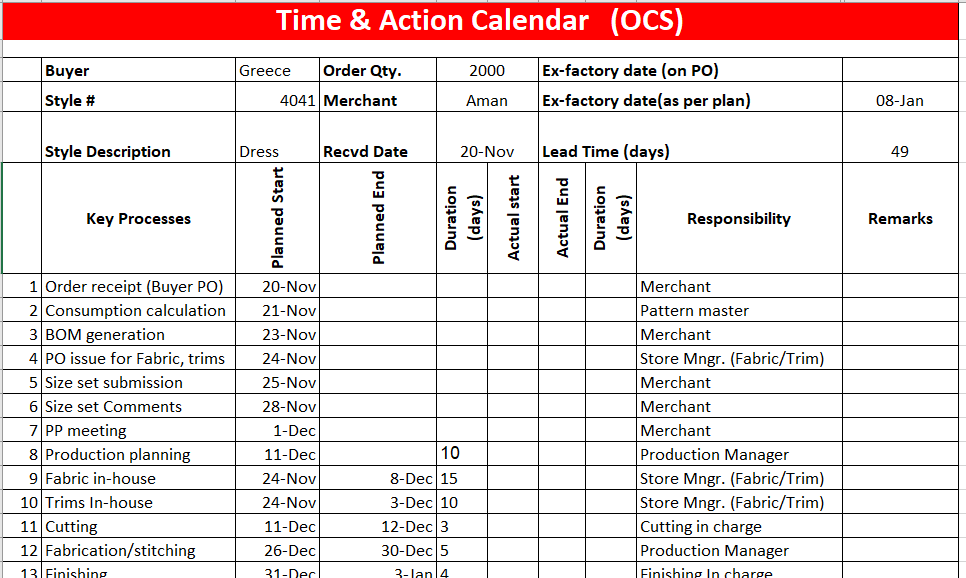

As we discussed in our previous blog post, a Time and Action Plan (TNA) is a tool used in the apparel industry to manage production. This helpful tool applies for every single garment category, including lingerie, swimwear, activewear, etc.

There are some key elements that an ideal TNA must have:

- Lead Times: the amount of time it takes to complete each stage of production, from design to delivery.

- Target Dates: the dates that each milestone should be met.

- Milestones: specific points in the production process, such as fabric arrival or sample completion.

Time and Action Plans help factories stay on schedule by providing a clear overview of the production process. You can use it to track progress and identify potential bottlenecks.

There are four factors you must consider when looking into creating a time and action plan:

1) Understand your product

2) Determine your lead times

3) Create a timeline

4) Assess your risks

Let’s take a closer look at each of these steps.

1) Understand your product: Before you can create a time and action plan, you need to have a clear understanding of your product. What are the materials? Then What is the construction? And then What are the details? Answering these questions will help you determine the lead times for each stage of production.

2) Determine your lead times: Once you have a good understanding of your product, you can start to determine the lead times for each stage of production. The lead time is the amount of time it takes to complete each stage, from design to delivery. To determine the lead times, you’ll need to talk to your vendors and other suppliers. They will be able to tell you how long it will take them to provide the materials or services you need.

3) Create a timeline: Once you know your lead times, you can start to create a timeline for the production process. The timeline should include all of the milestones for each stage of production, as well as the target dates for each milestone.

4) Assess your risks: Assessing risks is an important part of any manufacturing process, but it’s especially important when creating a time and action plan. There are many things that can go wrong during manufacturing. So it’s important to identify potential risks early so that corrective actions can be taken if necessary. Some common risks in apparel manufacturing include missing materials, delayed shipments, and quality issues. By taking the time to assess these risks upfront, you can avoid potential delays later on in the production process.