FIT WITH PRECISION

Mastering Technical Bra Fitting for Perfect Fit

Welcome, fellow designers and entrepreneurs of the intimate apparel world! Today, we embark on a journey to unravel the secrets of technical bra fitting. It’s a magical process that ensures our creations embrace every curve and provide unparalleled comfort and support. So, grab your measuring tapes and let’s dive into the world of precise measurements, fit corrections, and crafting the perfect intimate apparel.

DEFINING YOUR MODEL’S CORRECT COMMERCIAL SIZE

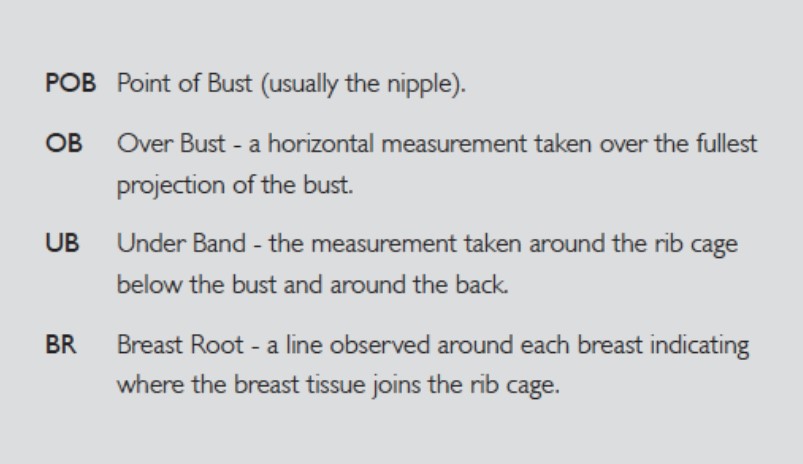

Let’s get down to the nitty-gritty of measurements, shall we? We’re talking about the POB, OB, UB, and BR – those numbers that help us crack the code of commercial sizes. But remember, we’re not dealing with mere averages here. No, no! Each woman is beautifully unique, and it’s crucial to honor their individual measurements, be it our lovely models or the end customers themselves.

THE FUNDAMENTALS OF FIT OR ‘FIT FOR PURPOSE’

When you lay eyes on a bra, what catches your attention? Hanger appeal is crucial, whether it’s in a store or a snapshot. But don’t forget about the touch and feel! The handle and weight of the garment provide valuable insights into tailoring, fabric suitability, and overall balance. Trust your instincts and let your refined judgement guide you.

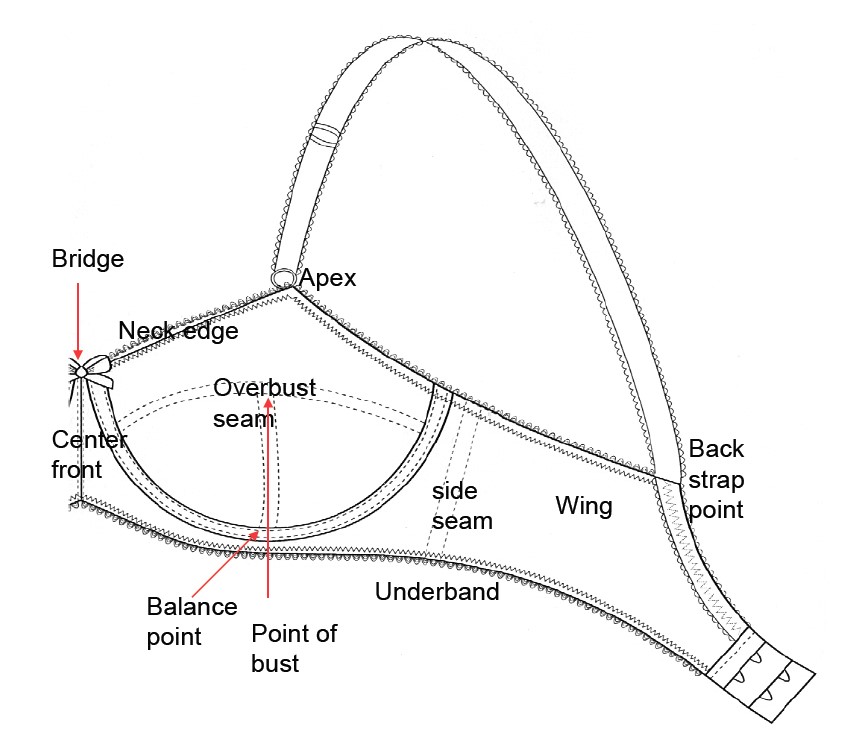

Now, let’s dissect the bra visually. Take note of the fabric, elastic widths, sewing construction, color matching, and labeling. Lay it flat on the table and assess its shape. Does it align with its intended function and size? As seasoned pattern-cutters, we can compare the style to our mental blueprint. It’s all about achieving that perfect match!

UNDERSTANDING HOW TO CORRECT FIT ISSUES

Fitting sessions can be a wild ride, but let’s make them more efficient, shall we? If a garment has more than two fit alterations, it’s time to wave goodbye and start fresh with a “parent” garment. Don’t settle for suppliers lacking technical expertise. Let’s keep those fit woes at bay!

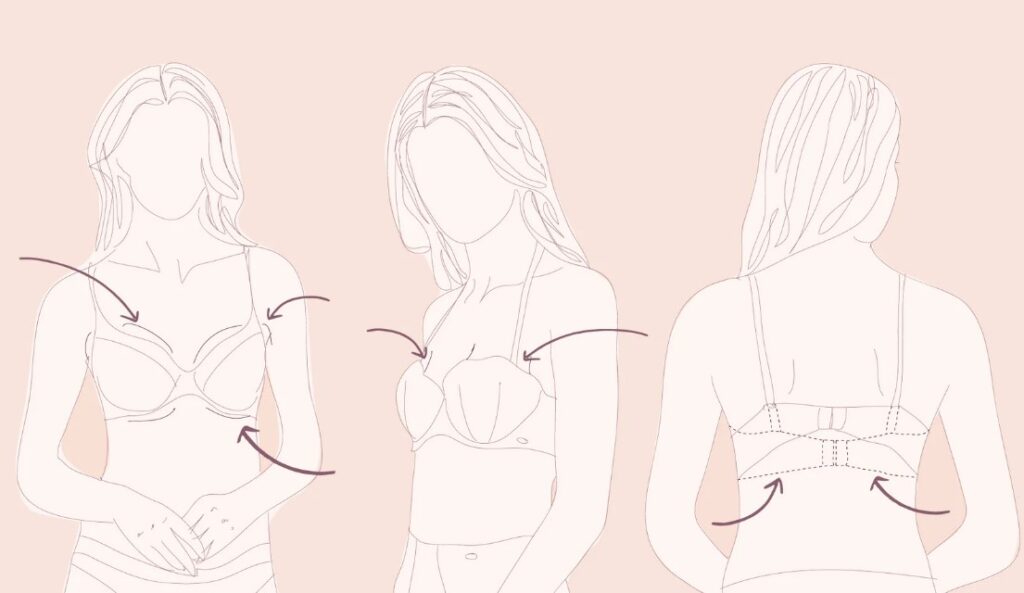

During fit sessions, demand a basic technical summary, size chart, wire sample, and amendment history. And here’s a secret tip: Models are humans too, and their size can fluctuate throughout the day. So, measure them not only in the morning but also in the afternoon. It’s all about precision, my friends!

Oh, and a little heads-up: Sample machinists may have a different standard compared to factory operatives. Keep an eye out for those differences and adjust accordingly. We want every stitch to be on point!

UNDERSTANDING WHAT MAKES A GOOD FIT

Here’s the deal: Fit is more than just numbers. We’re talking about garment engineering here! Look closely at the underband shape. It should hug the ribcage without smiling or looking flat. A “frowning” concave shape moulds perfectly around the body. Trust us; it’s a game-changer!

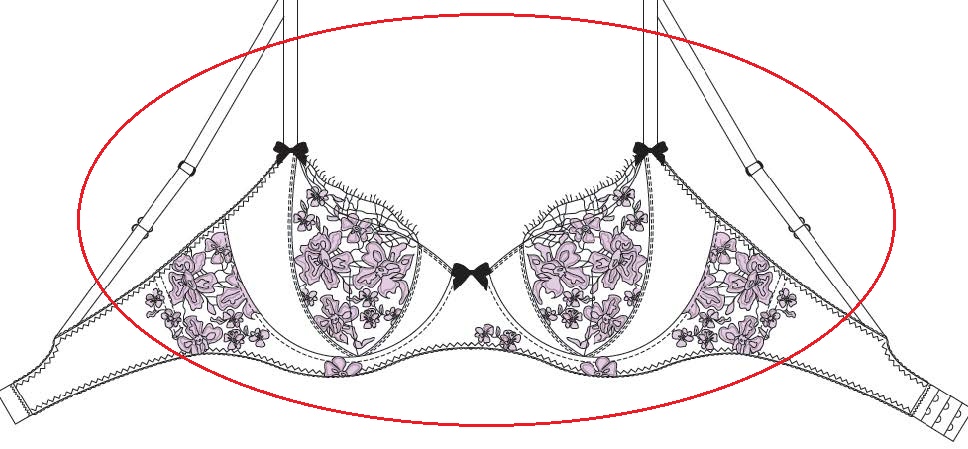

Now, let’s address cup sizing. Back in the day, the industry realized that a simple sizing system wasn’t enough. So, the alphabet cup sizing system was born. Forget the unflattering descriptions like “youthful” or “average.” It’s all about offering choices that cater to different body types. And remember, you can cross-grade every part of the bra within the circle, except for the wings. We love versatility!

When it comes to fabric selection, stick to the core range of tried-and-true materials. They’re technically sound, durable, and oh-so-comfortable. Beware of retail buyers demanding unusual fabrics that might not withstand the test of time. Let’s keep our lingerie game strong!

In the vast and ever-evolving world of intimate apparel, the significance of technical bra fitting cannot be overstated. Remember the importance of precise measurements, efficient fitting sessions, and choosing the right fabrics. With an eye for detail and a commitment to crafting bras that fit like a dream, you’ll create products that empower and delight your customers. So go forth, embrace the technical side, and let your designs shine with impeccable fit and style!