UNLEASH POTENTIAL

Santoni Seamless Knitting: Redefining Intimate Apparel Manufacturing

In the dynamic world of fashion and apparel, innovation is the key to staying ahead. One such ground-breaking technology that has transformed the intimate apparel industry is Santoni Seamless Knitting. With its ability to create flawless, seam-free garments, Santoni’s knitting process has revolutionised the way we design and produce lingerie, shapewear, and other intimate apparel items. In this blog post, we will talk about Santoni Seamless Knitting, exploring its capabilities, advantages, and impact on the industry.

THE BIRTH OF A NEW ERA

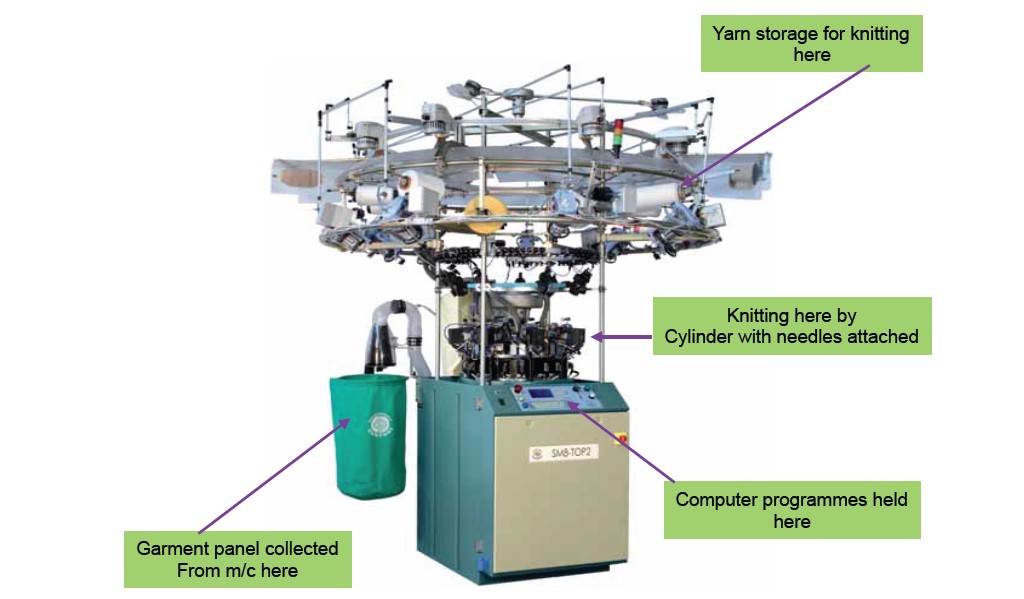

Imagine a knitting machine that can magically transform yarn into a complete, ready-to-wear garment. That’s the essence of Santoni’s seamless knitting process. Developed by the renowned Italian company Santoni, this technology allows for the creation of seamless garments with intricate designs and structures. As a designer, witnessing the birth of a fully formed circular garment descending from the knitting machine bed was nothing short of awe-inspiring.

UNDERSTANDING THE TECHNOLOGY

Santoni’s machines, typically ranging from 10 to 24 inches in diameter, are specialized circular knitting bed machines capable of producing shaped panels. These machines offer remarkable flexibility through different knit structures such as knit, purl, or tuck stitches. With a wide variety of fabric structures, garments, and hosiery produced in various diameters, circular knitting machines are frequently used to create intimate garments. While sleeves may be knitted separately and sewn on later, the main advantage lies in producing seamless sleeveless garments efficiently. Some Santoni machines can even create intarsia garments, resembling the techniques used in flat bed knitting machines.

ADVANTAGES OF SEAMLESS TECHNOLOGY

The Seamless technology pioneered by Santoni presents an innovative concept in lingerie production, nearly eliminating the need for traditional sewing. This approach offers several key advantages and features that make it a preferred choice for intimate apparel manufacturers:

- Reduced Costs and Improved Efficiency: The elimination of sewing and finishing processes significantly reduces labour costs and streamlines production. This means fewer machines are involved in the production flow, resulting in lower energy costs and quicker production times.

- Enhanced Design Flexibility: Seamless technology enables designers to create lingerie products with different layers, specific properties, breathability, engineered zones, and “wellness” applications. The capability to seamlessly transition from one yarn type to another expands the design options without compromising quality.

- Superior Comfort and Fit: Seamless garments offer unparalleled comfort, durability, and better fit. The absence of seams eliminates potential discomfort and irritation, ensuring a smooth and second-skin-like feel.

- Sustainable Production: The reduction in fabric waste and optimised production process make Santoni Seamless Knitting an environmentally friendly choice. The “just-in-time” production approach reduces yarn and fabric inventories, minimising waste and contributing to a more sustainable supply chain.

UNLOCKING THE POTENTIAL

To fully grasp the significance of Santoni Seamless Knitting, it’s essential to address some key questions frequently raised by industry professionals:

- Stitch Types and Functions: Santoni machines offer a range of stitch types. It has the ability to achieve different functions, such as tucks, floats, and false ribs. These variations enable designers to manipulate the shape, length, and unbalance of stitches, unlocking endless possibilities in garment construction.

- CAD Compatibility and Technical Drawings: Santoni machines have sophisticated programming capabilities. Designers can collaborate with CAD operators, providing them with technical drawings to bring their visions to life on the knitting machines.

- Speed Comparison with Cut-and-Sew: Santoni Seamless Knitting offers significantly faster production times as compared to traditional cut-and-sew operations.

- Cost Comparison: Investing in Santoni circular knitting machines represents a substantial financial commitment. However, the long-term benefits, including reduced labour costs and enhanced efficiency, can offset the initial investment.

- Yarn and Fibre Composition: Santoni Seamless Knitting employs a wide variety of yarns and fibres to achieve the desired outcomes for lingerie. For optimal stretch and control, Spandex coated with a continuous filament is employed. In addition, the incorporation of “hard” yarns like cotton, modal, or synthetic fibres adds the sought-after qualities of comfort and support, ensuring a unique and satisfying experience.

Santoni Seamless Knitting has revolutionized the intimate apparel industry, garnering widespread attention from start-ups and entrepreneurs. This innovative technology delivers numerous advantages, including cost savings, enhanced design flexibility, and superior comfort. By adopting Santoni Seamless Knitting, undoubtedly industry players can tap into limitless possibilities to create exquisite, functional, and sustainable intimate apparel that perfectly caters to the discerning tastes of modern fashion-conscious consumers.